Hi All,

There's not much else to do these days so I thought I'd bore you all with a few more posts. These could well be headed "Jobs that should

never have worked."

I need to fill you in on a bit of the background so you'll understand why I even attempted to do the job.

It was 1965, I was working for a company who had undertaken a contract to remove a waste tip from an old colliery in Newbridge, South Wales to make way for new playing fields.

The job entailed washing the coal out of the tip and disposal of the shale waste some two miles away.

At the center of the whole operation was a mobile Parnaby twin barrel washer. This was diesel electric powered and had it's own generator powered by an Armstrong Siddely ASJ4 engine. Hawker Siddely had taken over Lister/Petter and this engine was really a Petter PJ4 in Armstrong clothing.

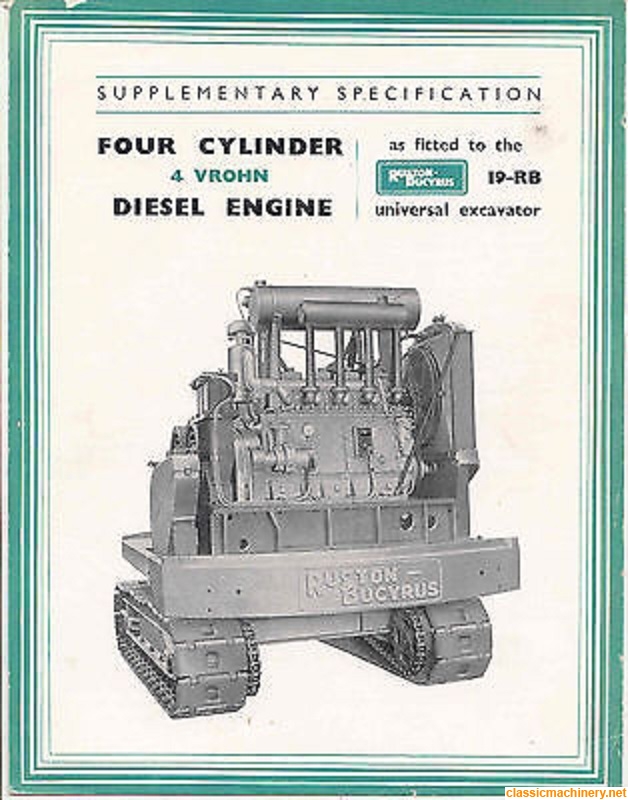

Keeping all this going was quite an operation employing two 19RB face shovels and two Leyland site tippers to feed the plant and a Smith Super 10 on grab to load the washed coal away onto a BMC 7 ton tipper. There was also a 19RB or a 22RB dealing with the slurry waste.

There was a Cat 955 or sometimes a 951 loading the shale away onto three or four Albion CD21 or CH13 road going tippers to dispose of the shale waste to tip and a Cat D4 at the tip end.

The wash-barrels were fed by one of the 19 RB face shovels via an old Parker Loader Screen from which the shaker screen had been removed. We had fitted the feed hopper with a Bar Screen to separate the large boulders.

This 19 RB was sat on a shelf on the side of the tip and fed by the site tippers tipping onto its shelf from above.

The only way onto and off the shelf for the 19 was up and down a very steep ramp.

On the day in question I was sat on a drum in the workshop welding, building up the faces of the dog clutches on an RB travel shaft when Bill, my boss, came in tearing his hair, (what was left of it), The 19 on the feed had developed a knock everything was on stop..

The driver had stopped it immediately and Bill who was no mean fitter himself had taken off one of the crank case side plates only to find that the crank shaft had cracked right through the web on No.4 nearest the flywheel end.

Everything was on stop. A dozen machines /lorries and fourteen or more men. " What are we going to do ," says Bill. " We have nothing that will pull that out of there."

Ivor, the transport fitter who worked with me said jokingly. " It's a wonder you don't want Fred to weld it isn't it Bill."

"That's an idea." Said Bill, and after telling him it couldn't be done that's just what we did.

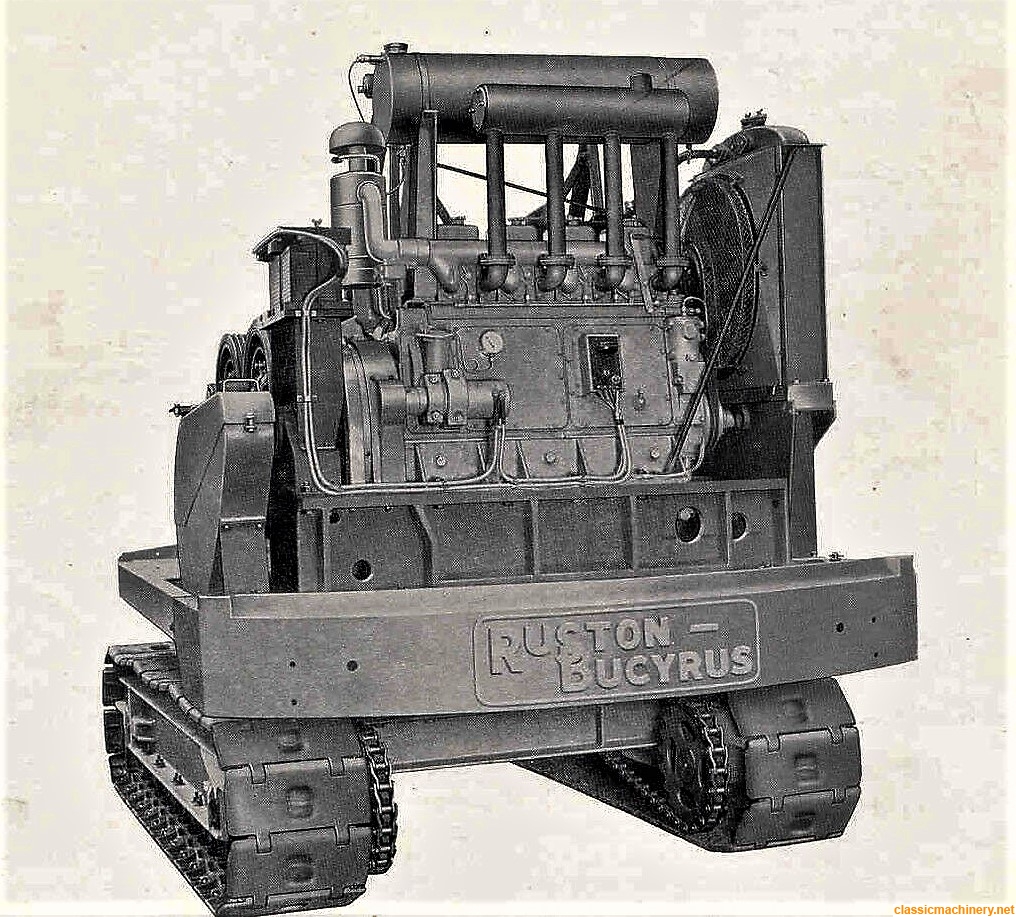

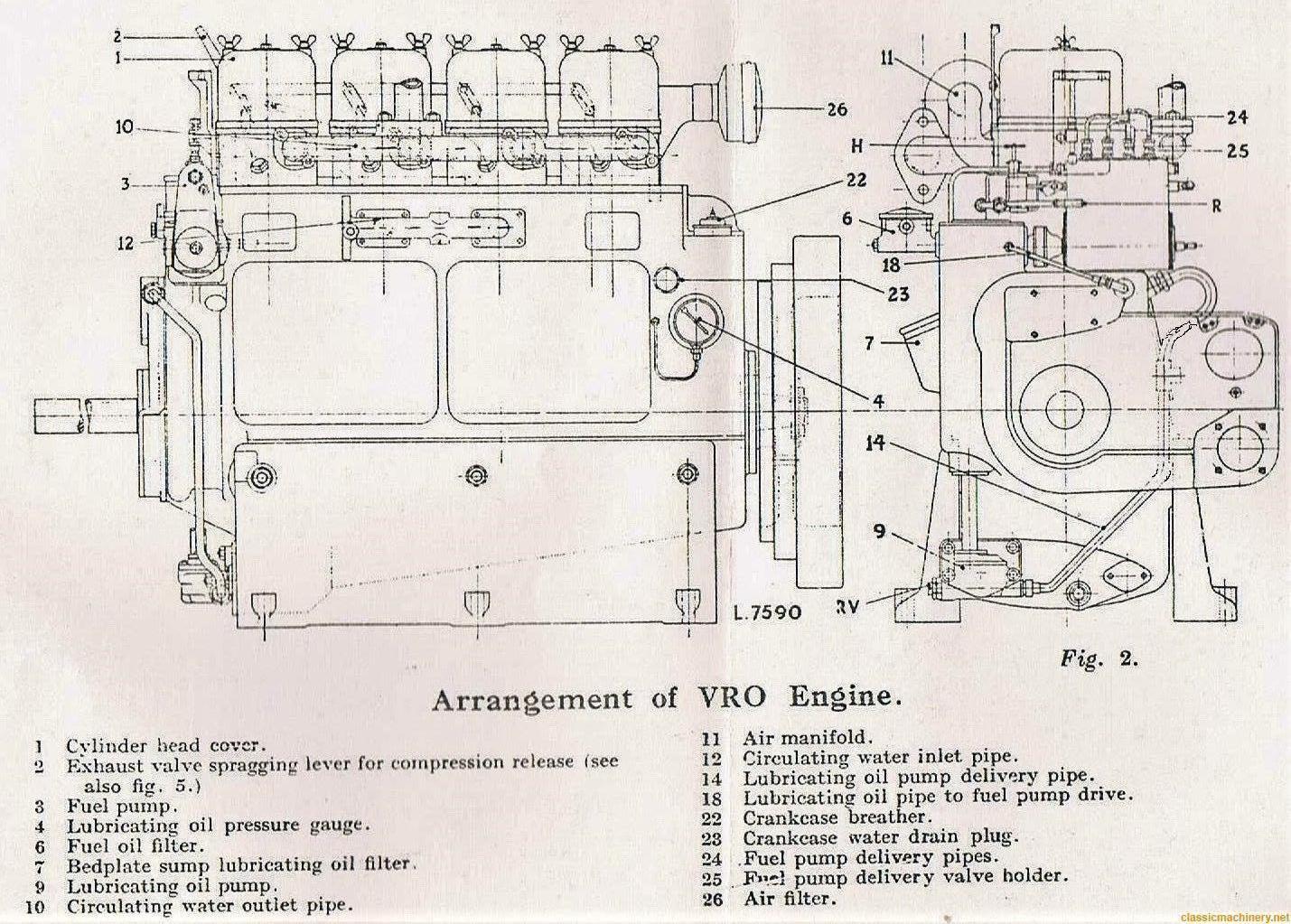

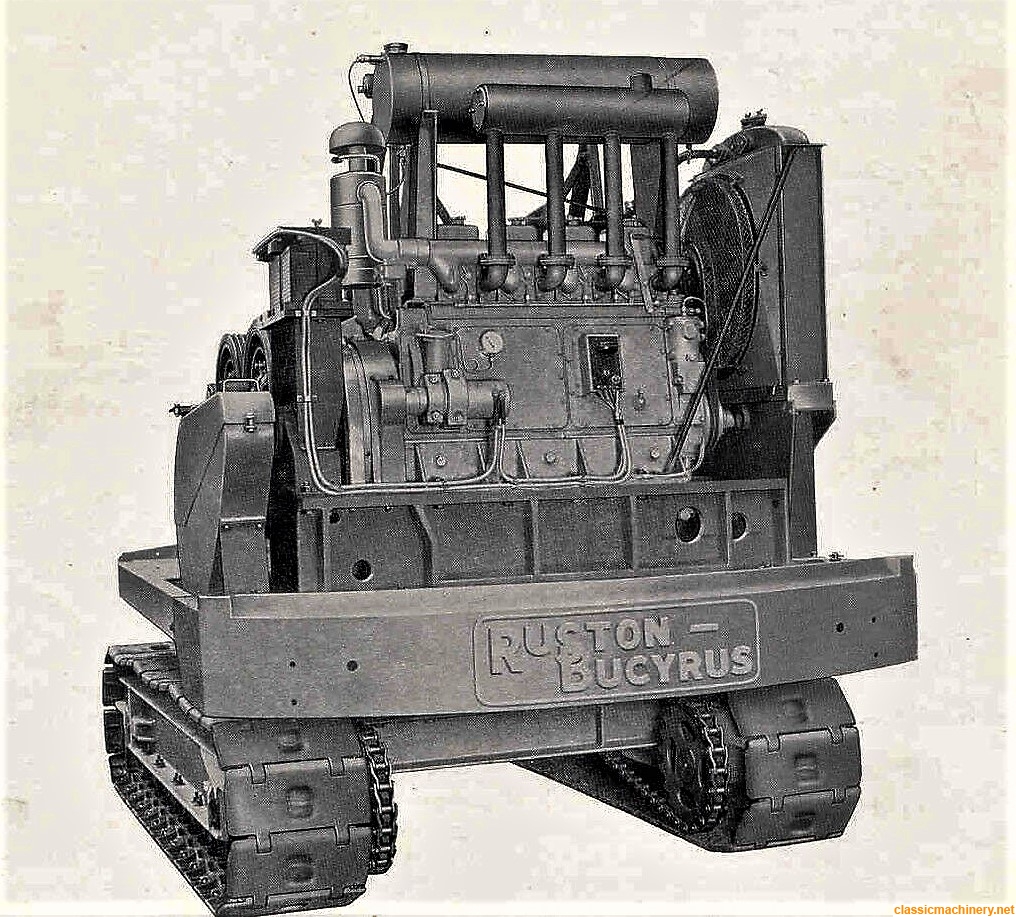

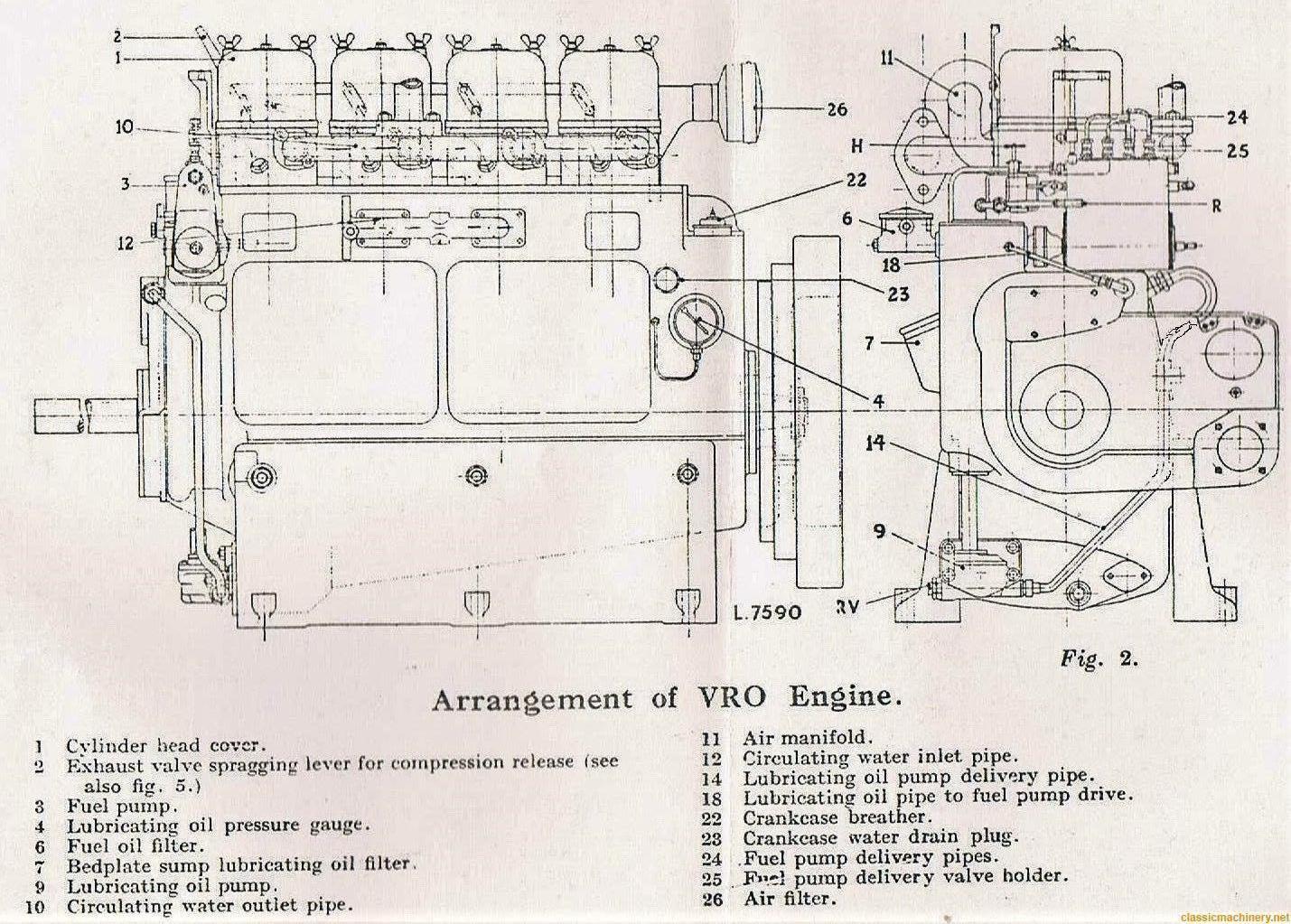

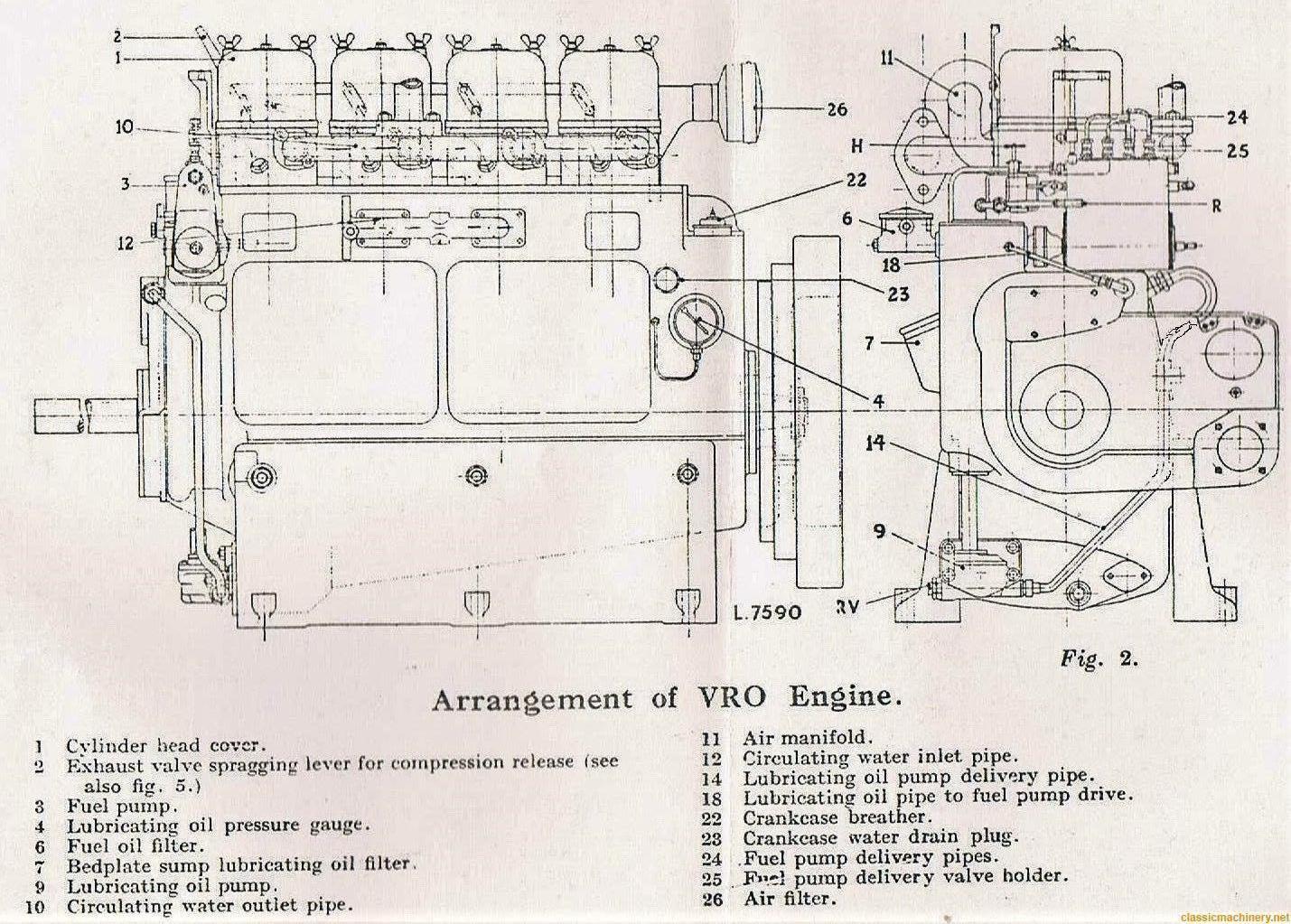

The engine in the New Improved 19 RB was the Ruston 4VROHN which has the timing gears at the back end between the flywheel and the block so there were multiple bearings supporting both ends of the broken crank and though the web had cracked right through there was little other damage.

Through the large crank case side panels, (once we dealt with the oil), we were able to get a tack each side of the break then gouge out the crack as deep as I dared with gouging rods, bearing in mind that there was an oil way in there somewhere. I then did the repair using ordinary low hydrogen electrodes.

"Yes it did run."

It ran long enough to climb out of its hole and get it back to the yard for an engine transplant.

But that's another story