The way we were

-

Jeremy Rowland

- Moderator

- Posts: 8676

- Joined: Sun Aug 05, 2007 8:36 pm

- Real name: Jeremy Rowland

- Has thanked: 1873 times

- Been thanked: 1691 times

Re: The way we were

Fred I have the second one somewhere it's a Gardner block spanner, the others could also be Gardner wrenches?

Jeremy

Jeremy

-

FOWLER MAN

Topic author - Posts: 2358

- Joined: Wed Dec 09, 2009 11:28 pm

- Real name: fred evans

- Has thanked: 1295 times

- Been thanked: 1111 times

- Flag:

Re: The way we were

Hi Pete and Jeremy,

You are both on the right track.

These spanners date back to a time when we didn't have the advantage of a torque wrench and obtaining the correct torque was down to the skill of the mechanic.

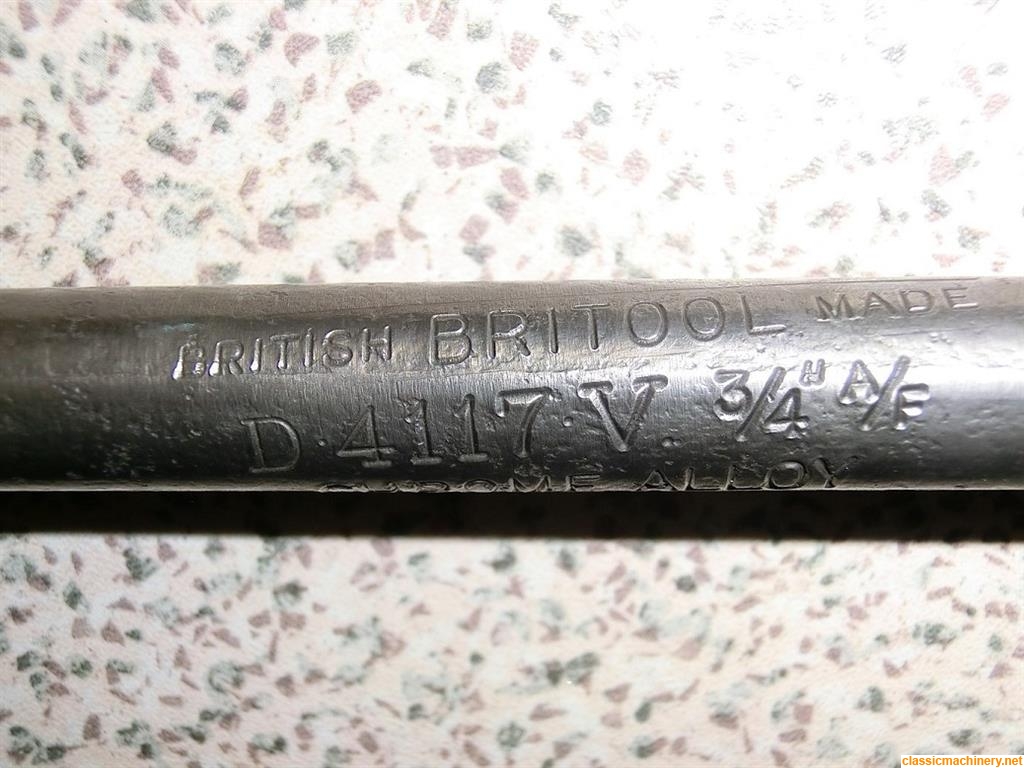

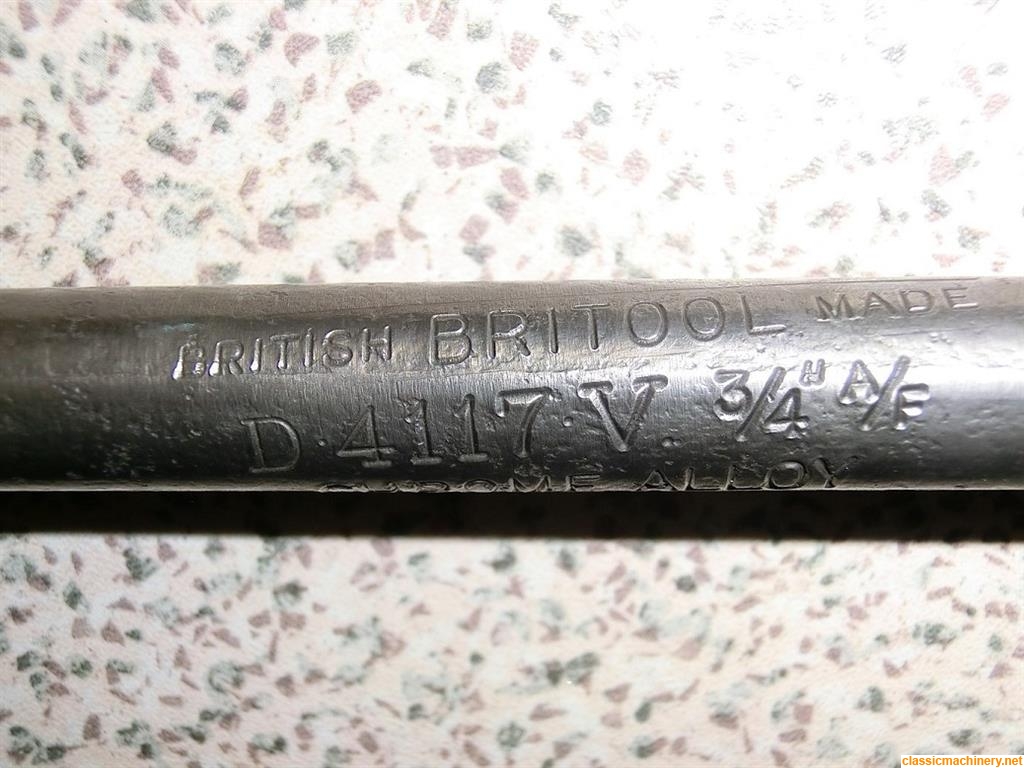

The two double ended ring spanners were made by "Brittool" for Bedford trucks, they were designed to be the right length for the average mechanic to achieve the correct torque with maximum hand pressure. The straight one appeared first but as Bedford recommended re-tightening when hot the cranked spanner was introduced to avoid having to disturb the rockers when doing this.

The other spanner is as Jeremy says is for Gardner head nuts and is also designed long enough to achieve the correct torque by hand pressure. This came with its own instructions cast in. ( see pic.)

It is for a Gardner LX engine and says "hand pressure only do not hammer". It also gives the torque setting 1,500 lbs. Inch. (That is equivalent to 125 lbs. ft.) Gardner engines never recommend re-tightening when hot.

Strangely enough my Gardner LX/LXH manual, ( from the torque wrench era), states the setting is 1200 lbs. in. or, (100 lb. ft. /13.8 kg. m.)

Fred

You are both on the right track.

These spanners date back to a time when we didn't have the advantage of a torque wrench and obtaining the correct torque was down to the skill of the mechanic.

The two double ended ring spanners were made by "Brittool" for Bedford trucks, they were designed to be the right length for the average mechanic to achieve the correct torque with maximum hand pressure. The straight one appeared first but as Bedford recommended re-tightening when hot the cranked spanner was introduced to avoid having to disturb the rockers when doing this.

The other spanner is as Jeremy says is for Gardner head nuts and is also designed long enough to achieve the correct torque by hand pressure. This came with its own instructions cast in. ( see pic.)

It is for a Gardner LX engine and says "hand pressure only do not hammer". It also gives the torque setting 1,500 lbs. Inch. (That is equivalent to 125 lbs. ft.) Gardner engines never recommend re-tightening when hot.

Strangely enough my Gardner LX/LXH manual, ( from the torque wrench era), states the setting is 1200 lbs. in. or, (100 lb. ft. /13.8 kg. m.)

Fred

-

modelman093

- Posts: 646

- Joined: Wed Jan 23, 2008 12:18 am

- Real name: Angus Shapland

- Has thanked: 8 times

- Been thanked: 72 times

- Flag:

Re: The way we were

Couldn't resist this for 50P in the local junk shop. For the Bedford 6 cyl petrol engines in the O, OY etc. Talking of those 6 cylinder lumps, the farm that I worked on before college in the 60s had several ex army OY and the farm mechanic used to adjust the tappets with the engine running using a Bedford part numbered feeler strip .

Sorry , the images have gone AWOL !!

Sorry , the images have gone AWOL !!

-

modelman093

- Posts: 646

- Joined: Wed Jan 23, 2008 12:18 am

- Real name: Angus Shapland

- Has thanked: 8 times

- Been thanked: 72 times

- Flag:

Re: The way we were

Hopefully the missing images from the previous post!! The one on the left is for doing Hillman Imp head bolts without having to remove the cam and the long one for Bedford 6cyl Head bolts/nuts.

-

Jeremy Rowland

- Moderator

- Posts: 8676

- Joined: Sun Aug 05, 2007 8:36 pm

- Real name: Jeremy Rowland

- Has thanked: 1873 times

- Been thanked: 1691 times

Re: The way we were

Thanks Angus  yes I have seen an engine tappets set with it running, can't think what it was now but that brings back memories.

yes I have seen an engine tappets set with it running, can't think what it was now but that brings back memories.

Jeremy

Jeremy

-

FOWLER MAN

Topic author - Posts: 2358

- Joined: Wed Dec 09, 2009 11:28 pm

- Real name: fred evans

- Has thanked: 1295 times

- Been thanked: 1111 times

- Flag:

Re: The way we were

Jeremy Rowland wrote:Thanks Angusyes I have seen an engine tappets set with it running, can't think what it was now but that brings back memories.

Jeremy

Hi Jeremy,

I remember working on an Armstrong Siddely engine with hydraulic tappets which were set running. We later converted the engine to solid tappets which were set in the normal way, ( an Armstrong modification for which a kit was available).

Fred.

-

FOWLER MAN

Topic author - Posts: 2358

- Joined: Wed Dec 09, 2009 11:28 pm

- Real name: fred evans

- Has thanked: 1295 times

- Been thanked: 1111 times

- Flag:

Re: The way we were

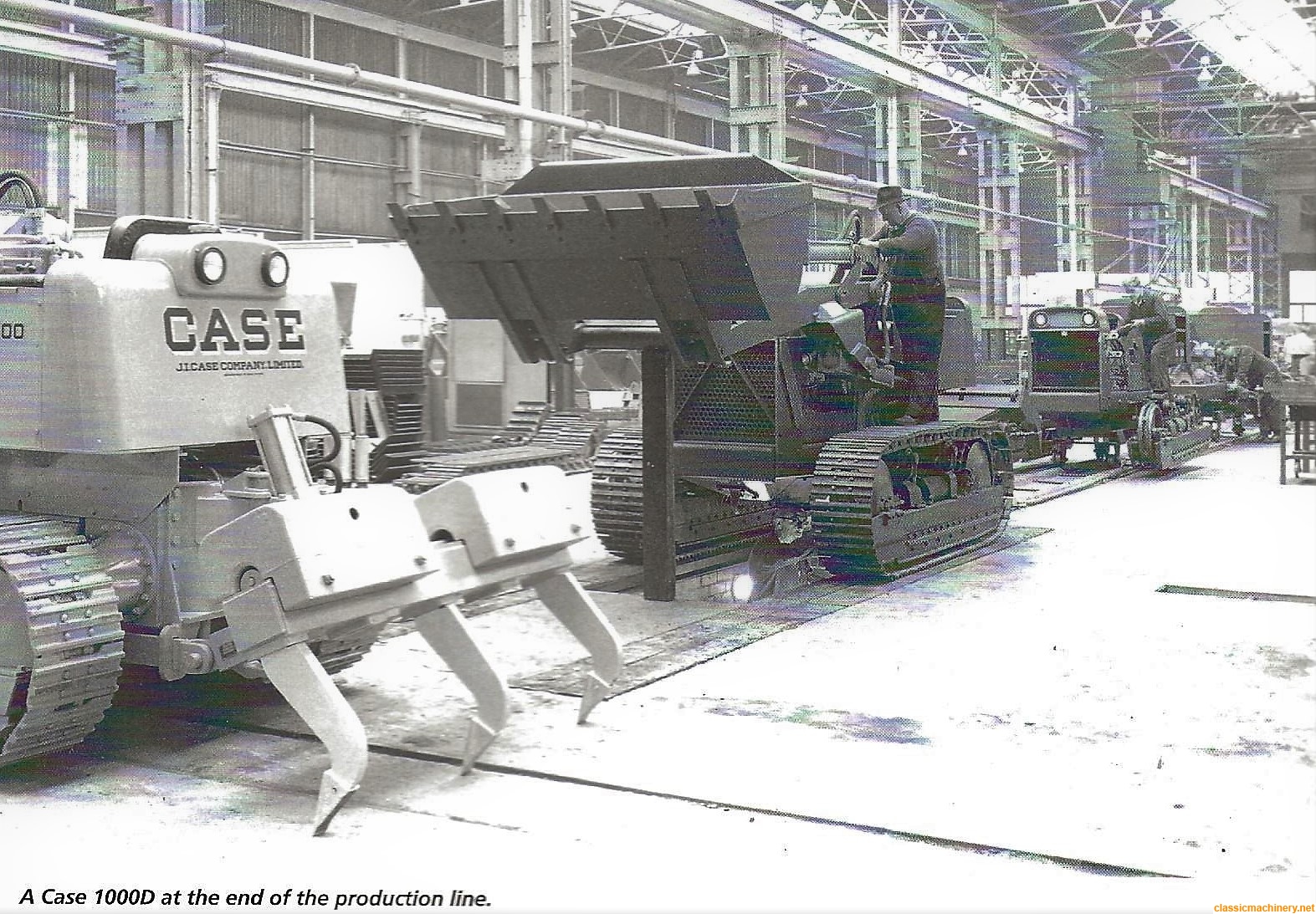

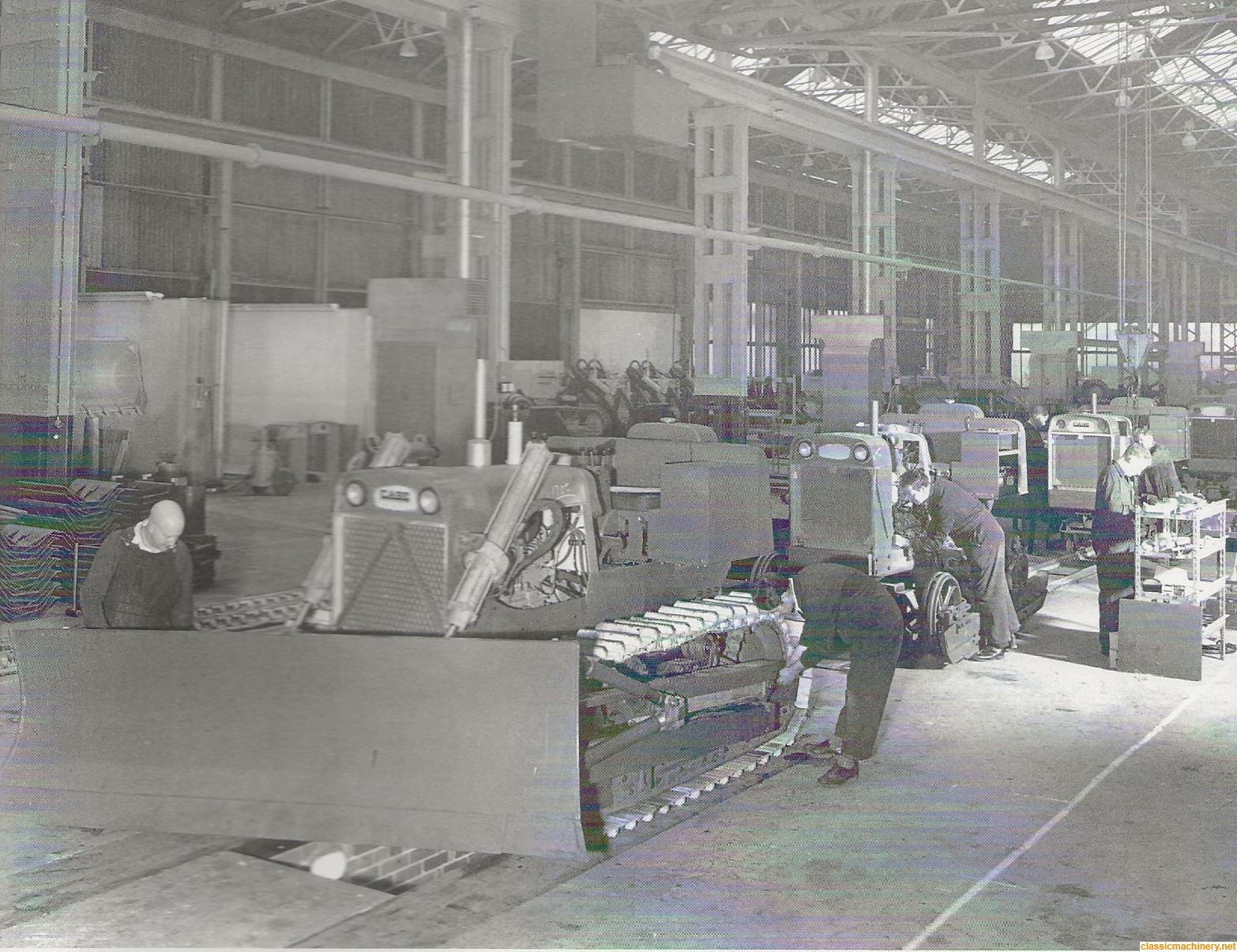

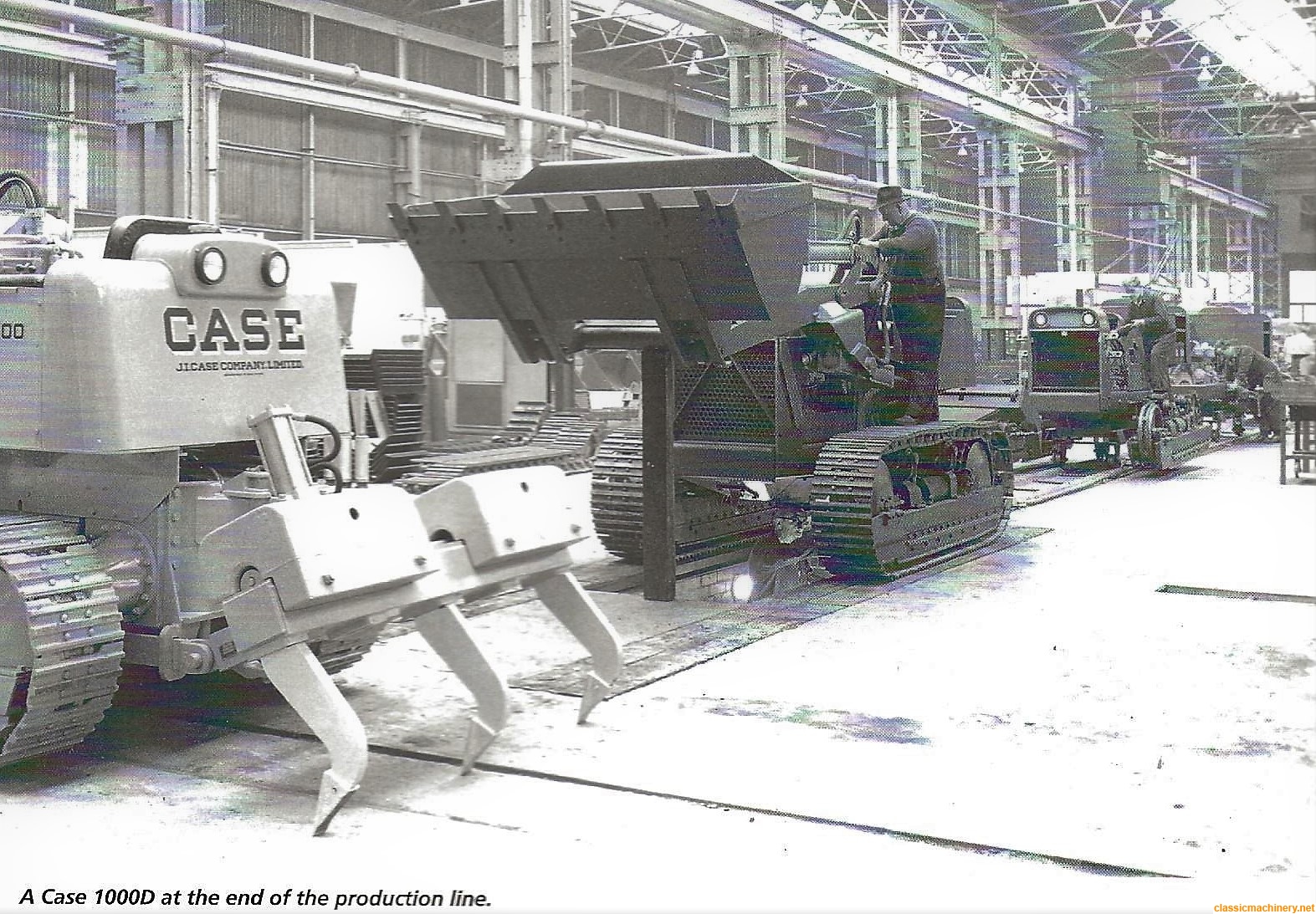

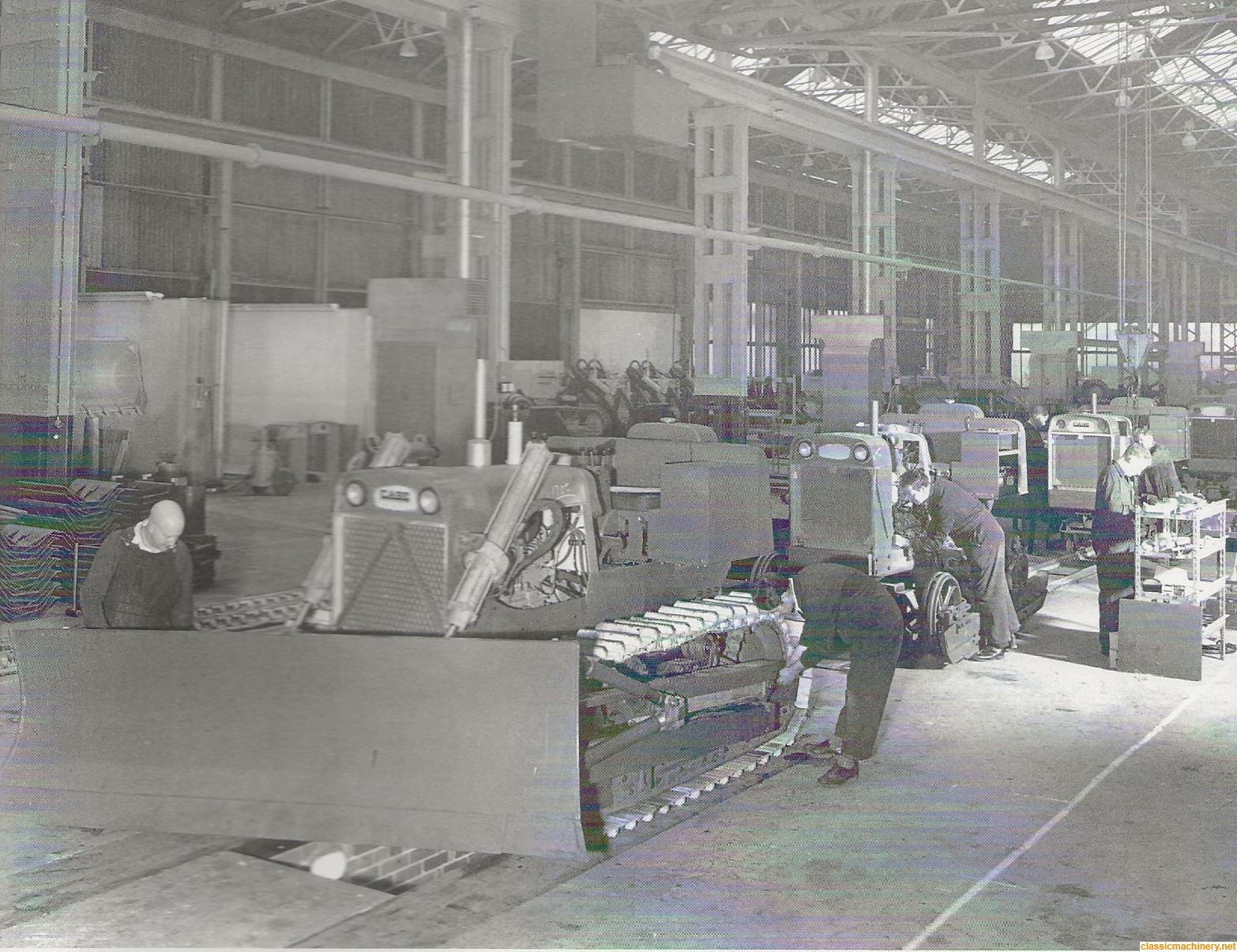

A couple of pics, here of the Leyland engined Case 1000 and Continental engined Case 850 tractors being erected in the works at Leeds.

Believe it or not, Case had leased the premises from the Fowler Company. This was the Fowler Works Where the Fowler Locomotives had been produced and was literally across the road from the Fowler Steam Plough Works where at the time Thomas Ward who owned Fowlers were producing the Challenger 33 tractors and Track Marshall shovels.

I worked on and operated both these unique Case models and they will feature in my next post.

Believe it or not, Case had leased the premises from the Fowler Company. This was the Fowler Works Where the Fowler Locomotives had been produced and was literally across the road from the Fowler Steam Plough Works where at the time Thomas Ward who owned Fowlers were producing the Challenger 33 tractors and Track Marshall shovels.

I worked on and operated both these unique Case models and they will feature in my next post.

-

Jeremy Rowland

- Moderator

- Posts: 8676

- Joined: Sun Aug 05, 2007 8:36 pm

- Real name: Jeremy Rowland

- Has thanked: 1873 times

- Been thanked: 1691 times

Re: The way we were

hair bear wrote:Clever how they've made it look like the Matchbox dozer.

As a kid I had the Matchbox Taylor Woodrow set, the Ford 'D' series truck, low-loader and Case bulldozer and the O&K MH6 and then later the Traxcavator, how I wish they'd made more construction models.

Jeremy

Return to “Misc earthmoving equipment”

Who is online

Users browsing this forum: No registered users and 6 guests