Hyster forklift

-

hubert

Topic author - Posts: 54

- Joined: Tue Dec 04, 2012 12:01 am

- Real name: Hubert Mooney

- Location: Ballymena, Northern Ireland

- Has thanked: 3 times

- Been thanked: 6 times

Hyster forklift

looking at a Hyster forklift with drive problems. When started cold in needs to sit ticking over for a few minutes before it will move. Also needs a lot of revs to get it to move. Oil level ok in transmission. Is the torque on its last legs? Thanks in advance for any help.

-

MrF

- Posts: 415

- Joined: Thu Mar 12, 2009 10:35 am

- Real name: Phil F

- Location: France

- Has thanked: 18 times

- Been thanked: 108 times

- Flag:

Re: Hyster forklift

I went through trans issues with my Hyster 2.5XL which I bought with various problems as a fixer upper, but that had the inverse, drive for the first minute then more rpm then finally no drive and worse in fwd than in reverse. It has a single speed powershift automatic transmission in it like quite a lot of the Hyster range...

A Hyster tech told me the most common issue they saw with this era machine was the wrong grade oil being used and that they are *really* fussy about grade, iso60 being harder to source than 46, and quite a lot of suppliers tried to fob me off saying it was equivalent after realizing they didn't have 60 in stock. I ended up having to import a drum from Germany in the end.

What I think was the final answer besides putting the correct grade of oil in it (the original oil that came out looked clean but too thin) and putting new filters to it, was cleaning out the area around the mesh filter in the sump in the trans which is a pig to get to and often missed. When I pulled the filter it was suspiciously clean, but it probably was a simple as the area around the pickup filter plugged with debris restricting flow... I think my machine had enough oil around the pickup sitting then when it drank this initial amount, pump pressures dropped and it lost drive.

As the forklift your looking at has the opposite case, I'd be wondering what grade of oil someone has put in it, and if they used too heavy oil, why they would do this. If so, could just be simple sloshing anything to hand in, or it could be to try to mask slipping of the clutch packs inside by making running pressures higher with thicker grade oil. You can fit a test gauge to the various test plug ports on the trans to diagnose pump pressures which will tell you the true story if the seller is interested in letting you do that.

Which model is it you are looking at? I might have the port/pump pressures etc info you need depending on model. Usual caveat, I'm not a auto trans specialist, just been through fixing my own and learned some stuff.

A Hyster tech told me the most common issue they saw with this era machine was the wrong grade oil being used and that they are *really* fussy about grade, iso60 being harder to source than 46, and quite a lot of suppliers tried to fob me off saying it was equivalent after realizing they didn't have 60 in stock. I ended up having to import a drum from Germany in the end.

What I think was the final answer besides putting the correct grade of oil in it (the original oil that came out looked clean but too thin) and putting new filters to it, was cleaning out the area around the mesh filter in the sump in the trans which is a pig to get to and often missed. When I pulled the filter it was suspiciously clean, but it probably was a simple as the area around the pickup filter plugged with debris restricting flow... I think my machine had enough oil around the pickup sitting then when it drank this initial amount, pump pressures dropped and it lost drive.

As the forklift your looking at has the opposite case, I'd be wondering what grade of oil someone has put in it, and if they used too heavy oil, why they would do this. If so, could just be simple sloshing anything to hand in, or it could be to try to mask slipping of the clutch packs inside by making running pressures higher with thicker grade oil. You can fit a test gauge to the various test plug ports on the trans to diagnose pump pressures which will tell you the true story if the seller is interested in letting you do that.

Which model is it you are looking at? I might have the port/pump pressures etc info you need depending on model. Usual caveat, I'm not a auto trans specialist, just been through fixing my own and learned some stuff.

-

MrF

- Posts: 415

- Joined: Thu Mar 12, 2009 10:35 am

- Real name: Phil F

- Location: France

- Has thanked: 18 times

- Been thanked: 108 times

- Flag:

Re: Hyster forklift

I've already posted the ports stuff on this site but here again :-

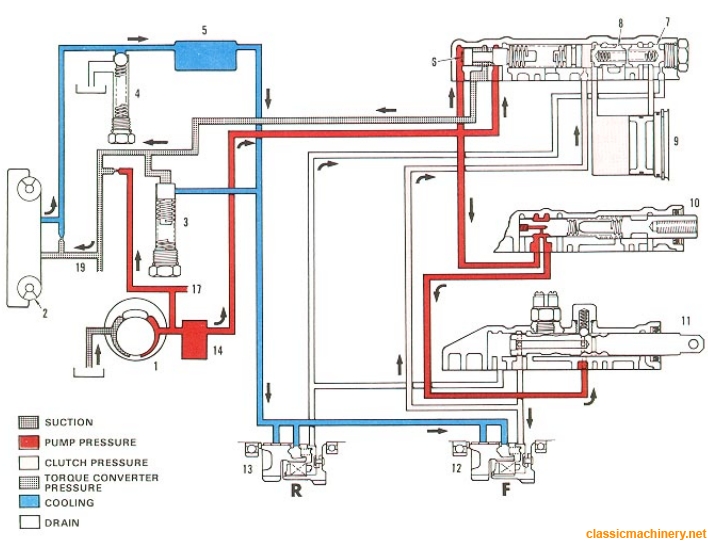

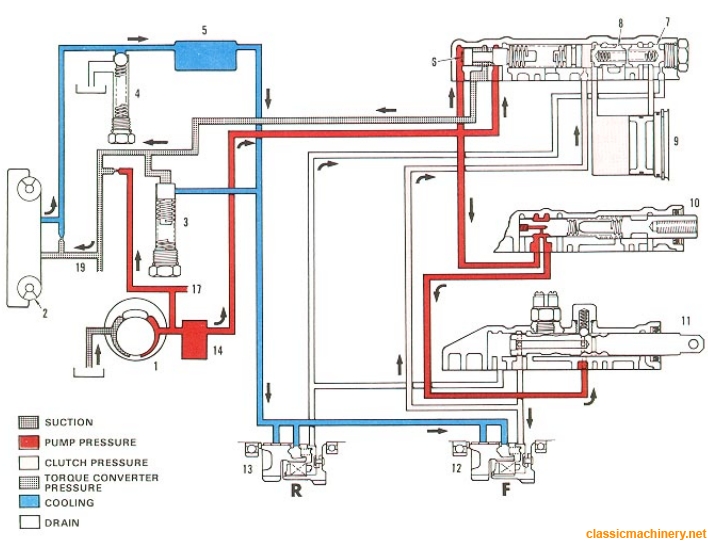

And this is what the oil circuits that control it look like, as you can see there's a lot of places it can go wrong or have valves stick. At one point I found the relief valve stuck at #3 that I thought was my issue...

And this is what the oil circuits that control it look like, as you can see there's a lot of places it can go wrong or have valves stick. At one point I found the relief valve stuck at #3 that I thought was my issue...

-

hubert

Topic author - Posts: 54

- Joined: Tue Dec 04, 2012 12:01 am

- Real name: Hubert Mooney

- Location: Ballymena, Northern Ireland

- Has thanked: 3 times

- Been thanked: 6 times

Re: Hyster forklift

Was the problem just the wrong grade of oil as well as a good clean out of the filters? Did you need to put in new clutch packs and if so was it expensive to repair?

-

MrF

- Posts: 415

- Joined: Thu Mar 12, 2009 10:35 am

- Real name: Phil F

- Location: France

- Has thanked: 18 times

- Been thanked: 108 times

- Flag:

Re: Hyster forklift

I bought it knowing full well it had no drive and didnt run that well, but I paid a suitably low price for a forklift with various issues & yes, It was a damn good clean out of the sump to remove the debris, a valve stuck, clean correct grade of oil and new transmission filter. I was thinking round what the issue was then I got the gauges on the test ports and went through the book and things pointed to oil flow issues as there was too low pressure on a few tests. I had the valve block off the top and stripped and cleaned it and the relief valves out also looking for the issue.

There's a hyster group on facebook I was in at the time and some of the people in there were hyster techs and really clued up & that's where I was told about the grade of oil being really important. And I hunted down the complete manual set for my exact machine which was a mine of information.

I didn't have to do the clutch packs, at one point I was thinking they or the pump were the fault and started pricing the job up & for my specific model the plates are not that expensive themselves to buy and it depends if you just need frictions or steels too, if the pumps ok or saveable or needs a new one etc. I think the worst of the job is taking the transmission out and splitting it to get to the clutch or pump as there's various schools of thought on what has to come off first to do this with some people saying mast/front axle, some saying engine out then work on it from inside the space cleared, but either way it sounds a pig to get to, so you would want to renew both while you were in there and use new seals so a few hundred euro on parts alone for sure. And the torque converter itself seems to be really expensive if it needs one although you might find somewhere that can recon it or get lucky and drop on one on ebay and import it.

When the machine is lifting something near its capacity up the ramp to my workshop I do have to gun it a bit but its steeper than the max recommended angle for a ramp in the hyster manual after we screwed up a calculation building the workshop ramp shutters. On the flat or gentler inclines its fine. I have used it to wheel around my machining centre at 4t picking up one side with the other sitting on skates no issues so its fair to say it has plenty of drive.

I found these guys great for parts but their website was terrible and they reckon its undergoing overhaul when I pointed out some issues, but they may have fixed them by now. I'll ring them up for parts and order over the phone if I need more stuff though.

https://www.lsforklifts.com/c78593/tran ... discs.html

There's a hyster group on facebook I was in at the time and some of the people in there were hyster techs and really clued up & that's where I was told about the grade of oil being really important. And I hunted down the complete manual set for my exact machine which was a mine of information.

I didn't have to do the clutch packs, at one point I was thinking they or the pump were the fault and started pricing the job up & for my specific model the plates are not that expensive themselves to buy and it depends if you just need frictions or steels too, if the pumps ok or saveable or needs a new one etc. I think the worst of the job is taking the transmission out and splitting it to get to the clutch or pump as there's various schools of thought on what has to come off first to do this with some people saying mast/front axle, some saying engine out then work on it from inside the space cleared, but either way it sounds a pig to get to, so you would want to renew both while you were in there and use new seals so a few hundred euro on parts alone for sure. And the torque converter itself seems to be really expensive if it needs one although you might find somewhere that can recon it or get lucky and drop on one on ebay and import it.

When the machine is lifting something near its capacity up the ramp to my workshop I do have to gun it a bit but its steeper than the max recommended angle for a ramp in the hyster manual after we screwed up a calculation building the workshop ramp shutters. On the flat or gentler inclines its fine. I have used it to wheel around my machining centre at 4t picking up one side with the other sitting on skates no issues so its fair to say it has plenty of drive.

I found these guys great for parts but their website was terrible and they reckon its undergoing overhaul when I pointed out some issues, but they may have fixed them by now. I'll ring them up for parts and order over the phone if I need more stuff though.

https://www.lsforklifts.com/c78593/tran ... discs.html

Who is online

Users browsing this forum: No registered users and 28 guests