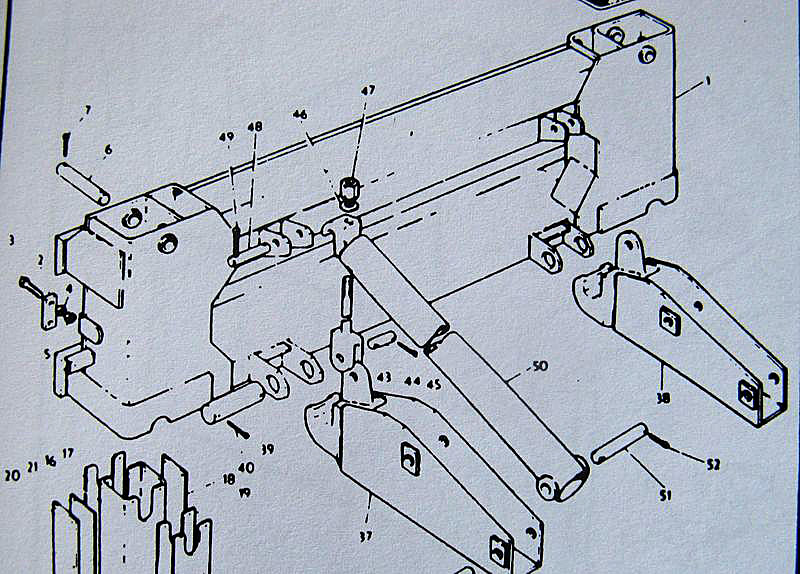

I wondered if anyone had any suggestions for how to fix or improve this problem. On the 50B the backactor frame mounts to the "tractor" by two arms from underneath, and two from above. The frame rests on the lower arms, and is held down by the upper. The upper and lower arms are tied together on each side by a near vertical rod threaded for a very deep nut at the top. The diagram roughly shows it except that on my digger the upper arm (50) looks like its part of the chassis and not removable.

URL of the original image: http://i42.photobucket.com/albums/e320/GandyGoose/YBW/IMG_0789C_800.jpg

My problem is that there is movement between these, so the backactor frame can move relative to the tractor. To fix it, I assume the nuts on the vertical rods should be tightened, but so far I have been unable to move it. The nut looks to be peened in place, and even looks like a hole's been drilled to weld the nut. See picture..

URL of the original image: http://i42.photobucket.com/albums/e320/GandyGoose/YBW/IMG_0788_800.jpg

Given that the rod had the immovable nut on the top, and a fork at the other end, I can't even remove it altogether to try and sort it out in the workshop.

Any ideas? The movement worries me, it can't be right and I think it could even be dangerous.

Thanks in advance, Tony S