Well life has been busy of recent and getting up to said Poclain and Hymac have been a problem for me I like to book a Thursday off work to go up there as Andrew Beaulah and the other lads who work on the machines are present however I have just been too busy so I managed to get in a 'flying' visit on a couple of Saturdays.

My plan is to cure the oil leaks on the Poclain and get it working ready for the working event in early July all being well, this will give me more time to concentrate on working on some of the bigger jobs on the Hymac. The first job was to get the machine running I had to borrow a battery off Andrew to get her started as one of the batteries on there is knackered, I also fitted a spare ignition switch that I have and got her running off the key.

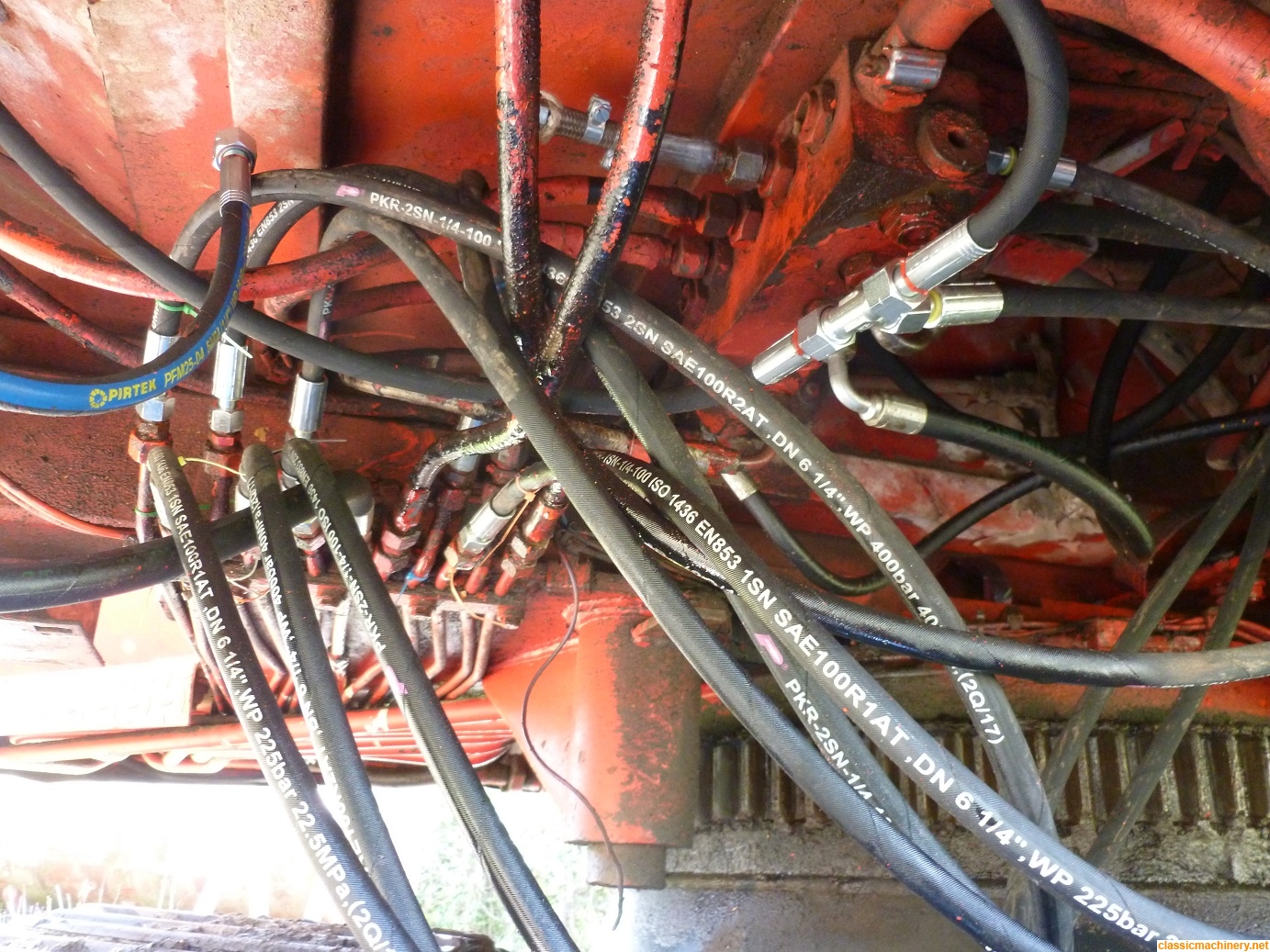

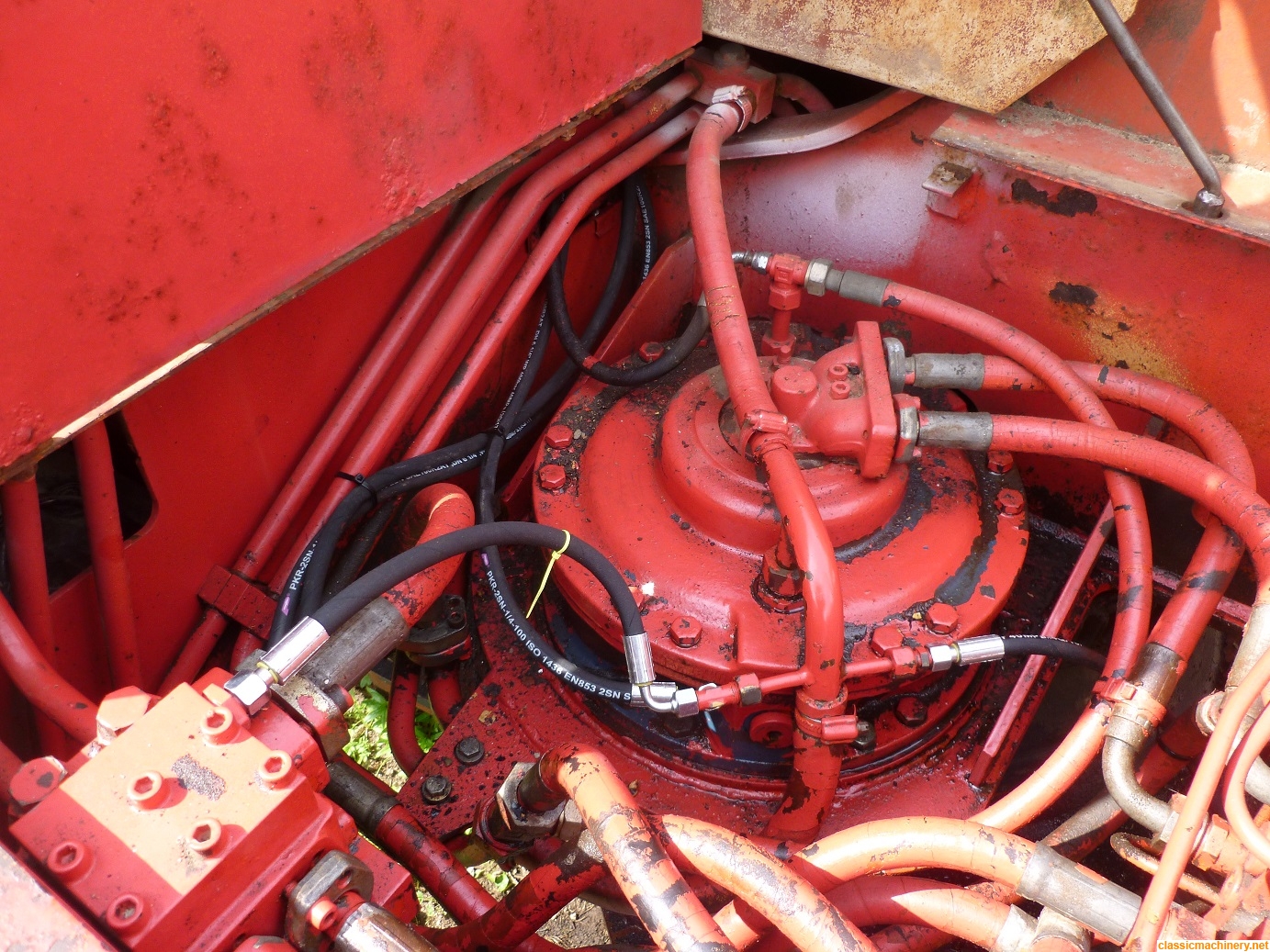

Working on this machine is a whole new learning curve for me because even as a kid I had worked out how a Hymac worked but Poclain are a slightly different ball game; the machine has leaks from two different areas, one under the cab and the other leaks on the main body of the machine on the hydraulics at the front offside of the digger.

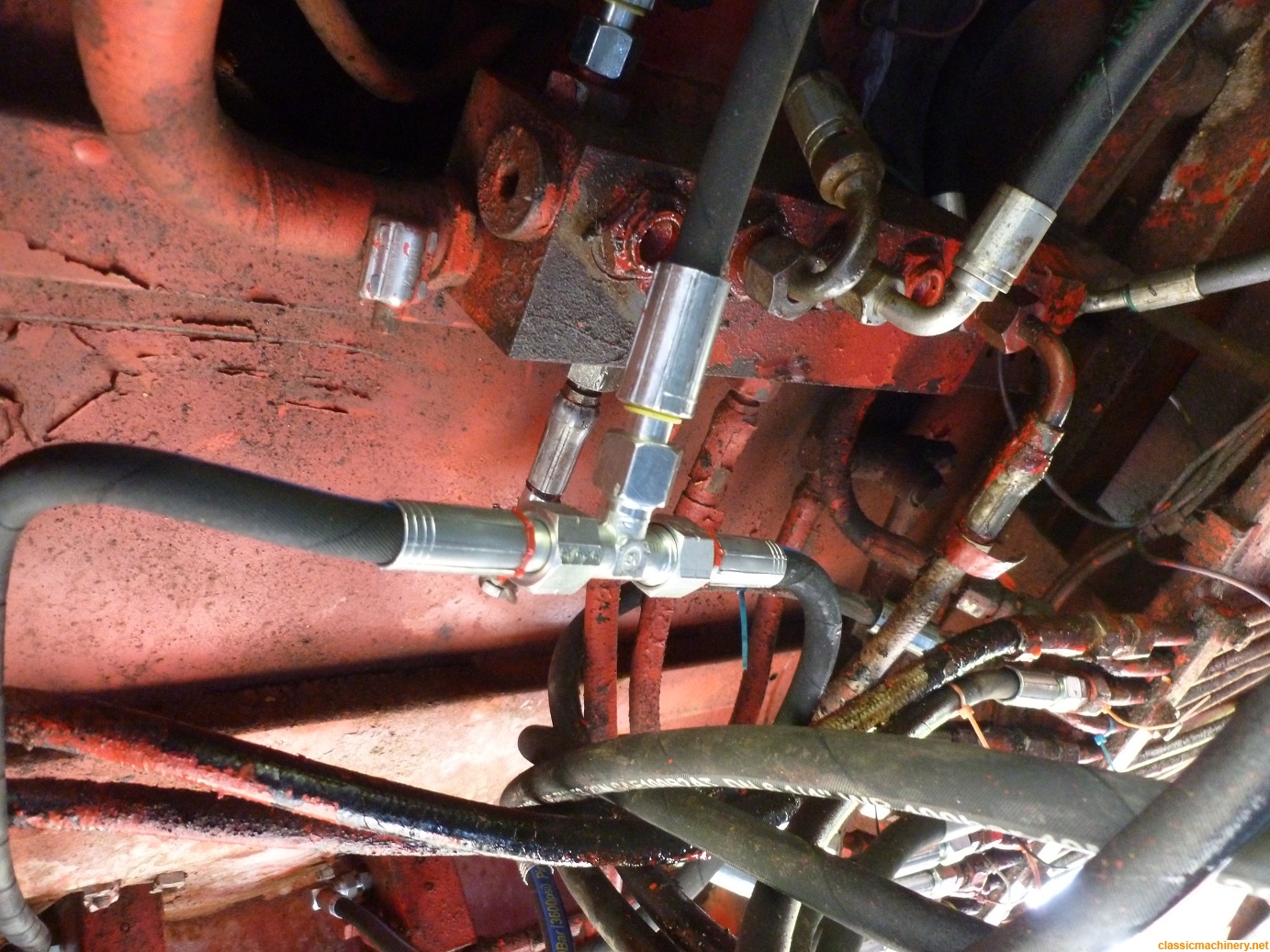

I decided that I would tackle the awful job under the cab first so I positioned the cab half way over the tracks to enable me to get some access underneath the cab, the small feed pipes run from across the offside of the excavator underneath the upper body to the underside of the cab where they disappear in three areas, one feed goes to the track drive activation pedals and the other two are split and enter the cab through two holes either side of the operators seat where they feed the control levers.

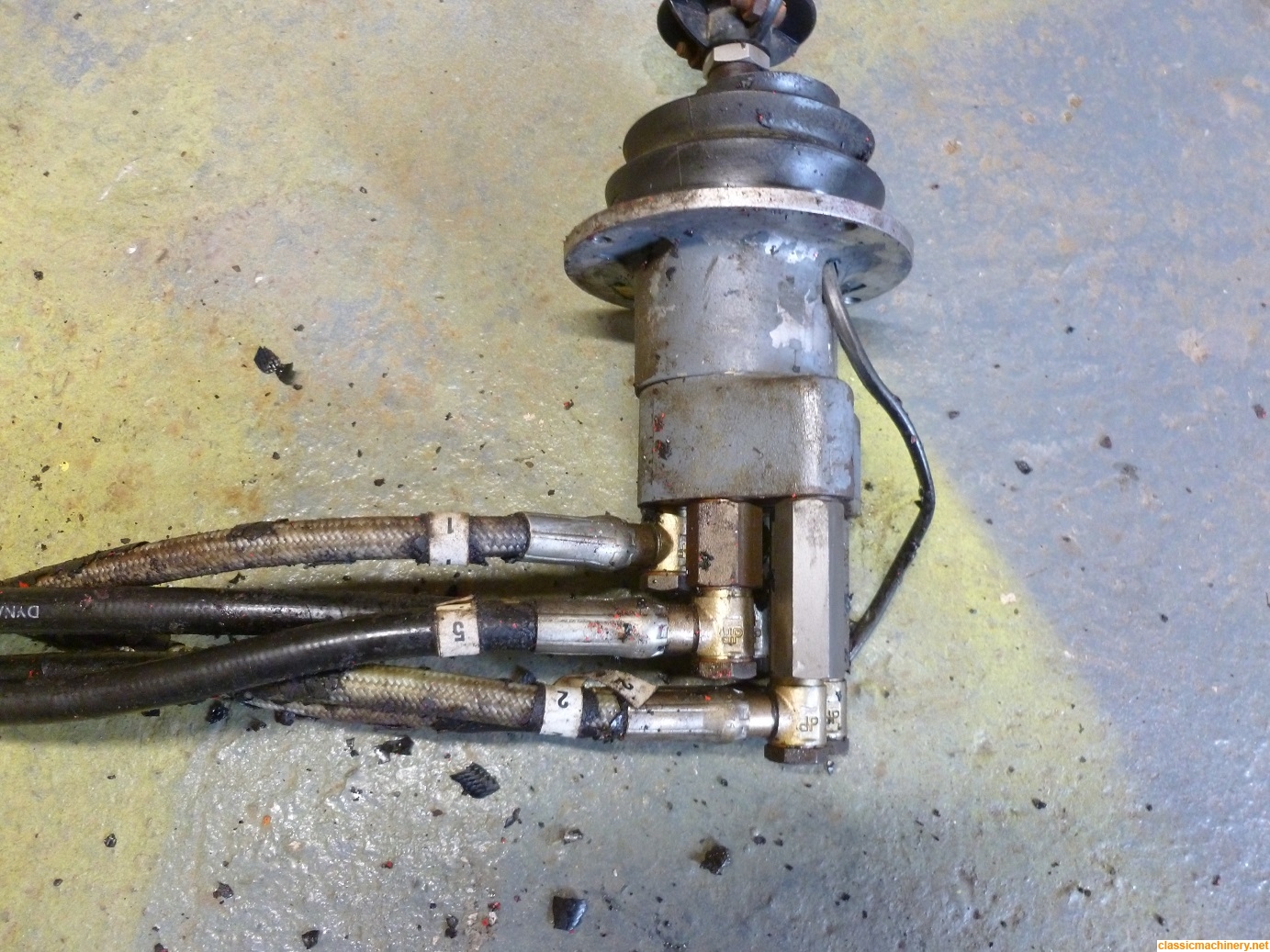

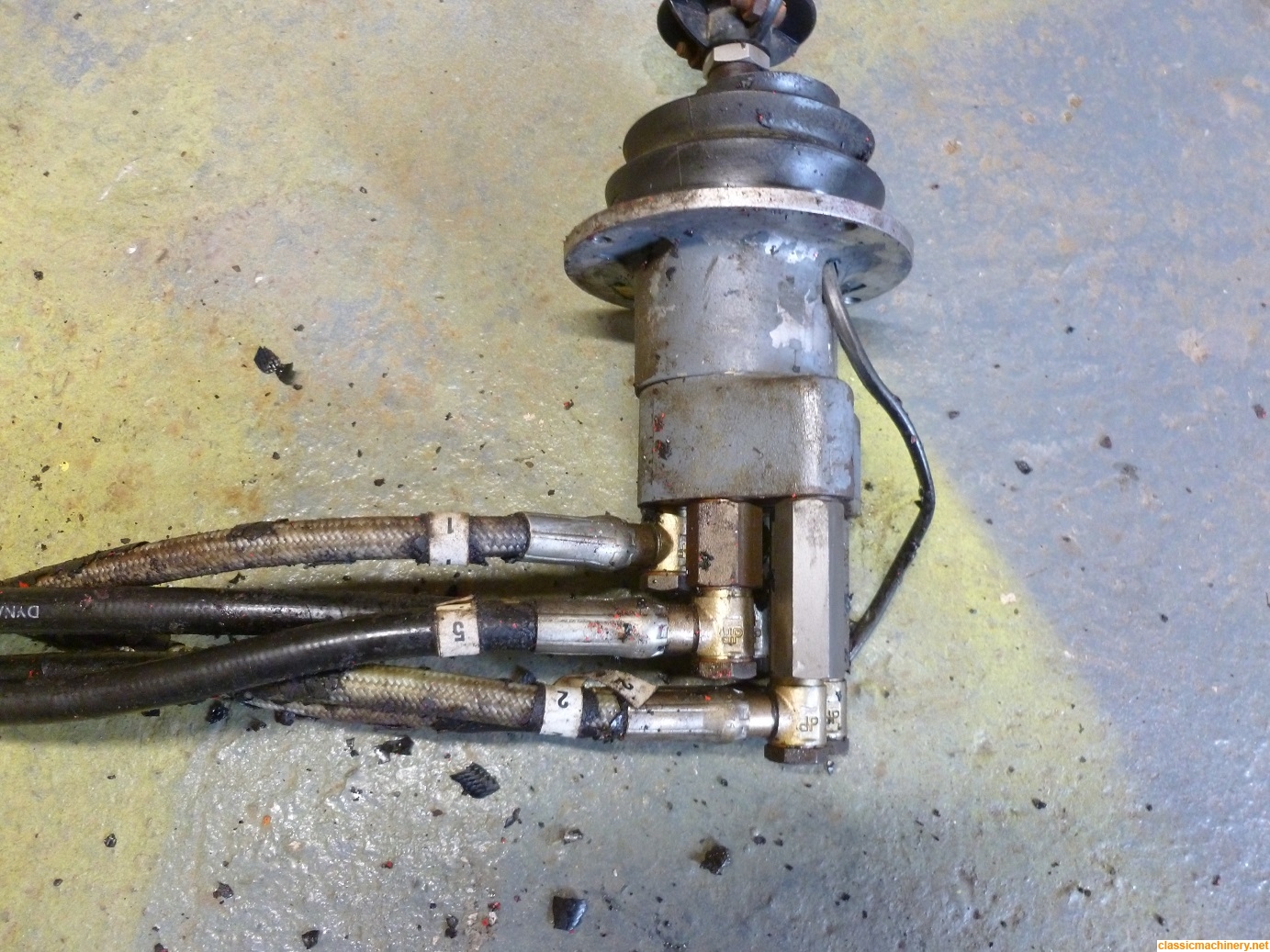

These hydraulic pipes are crappy nylon affairs of which it was hard to see exactly which of them was leaking so I decided that I would tackle each control lever individually, the left hand lever had all old pipes on it with the exception of one, they were numbered but this is of no help if you are taking them all off which I was so I opted to mark them with coloured cable ties and photograph them as well for further reference.

I have now got the left lever done and the knackered pipes off the right lever and one of the track pedal pipes which will be replaced, once I have cured the under cab leaks I can then concentrate on the other leaks, the levers require patience it is a fiddly job so I just hope that all works without any further leaks when I am ready to start the machine to test her out.

Jeremy

I will be giving updates as the work progresses although I still have much to do on the Hymac, whatever the work on both machines will get done as I'm both determined and eager.

I will be giving updates as the work progresses although I still have much to do on the Hymac, whatever the work on both machines will get done as I'm both determined and eager.