Jeremy

Hymac 580BT 1969

-

Jeremy Rowland

Topic author - Moderator

- Posts: 8677

- Joined: Sun Aug 05, 2007 8:36 pm

- Real name: Jeremy Rowland

- Has thanked: 1873 times

- Been thanked: 1692 times

Re: Hymac 580BT 1969

Thanks Alex  I already have a tool made up to remove the cylinder cap; however there is some small damage to the rod so I may end up simply fitting a second hand one, just have to see how things plan out.

I already have a tool made up to remove the cylinder cap; however there is some small damage to the rod so I may end up simply fitting a second hand one, just have to see how things plan out.

Jeremy

Jeremy

-

Jeremy Rowland

Topic author - Moderator

- Posts: 8677

- Joined: Sun Aug 05, 2007 8:36 pm

- Real name: Jeremy Rowland

- Has thanked: 1873 times

- Been thanked: 1692 times

Re: Hymac 580BT 1969

I managed to get up to my machines on Thursday and it was time to put some more effort into the restoration of my Hymac my intention was to fit the two boom hoist rams which I have had reconditioned.

After disconnecting the hydraulic oil hoses I removed the grub screw that secures the cylinder shackle pin, I had previously checked that these grub screws would come out as they both looked to be very rusted in, as it happens they came out easily.

I popped the circlip off the top of the outer cylinder and tied it off with some rope, it came off the pin without me having to knock the pin through because there was much wear in the bottom bush. I put a sling around the cylinder and carefully took the weight with the Poclain while I slid the bottom cylinder shackle pin out.

After I had cleaned the bits and pieces up, the new cylinder was lifted into place using the Poclain and the cylinder bottom pin slid partially through the bottom eye of the cylinder. There is some wear around 0.030" on the actual frame where the cylinder pins slide through but this will have to pass at the moment.

Aligning the top piston pin up proved to be more trouble trying to use the Poclain added to which I did not want to accidentally clout the Hymac with the said machine, so it was easier for me to get another of the lads there to physically lift the reconditioned ram vertical and hold it there while I put a sling around the top of the ram and connected a pull lift to the sling. I then connected the hydraulic hoses and used the Hymac to push the piston out to near where it should fit then hoisted it using the pull lift, after some effort the cylinder was duly fitted and the other one I fitted faster as I then knew the best way to tackle the job. The only other issue was that I could not get the circlip back on the top of the second ram so I used a ratchet strap to pull the cylinders together and then the circlip fitted no problem.

I did have a quick play on the machine and it now works as it should; the right hand ram (nearest the cab) had the inner seals gone and the oil was bypassing them so she would not lift the boom under load, so another job bites the dust but lots left yet.

Jeremy

After disconnecting the hydraulic oil hoses I removed the grub screw that secures the cylinder shackle pin, I had previously checked that these grub screws would come out as they both looked to be very rusted in, as it happens they came out easily.

I popped the circlip off the top of the outer cylinder and tied it off with some rope, it came off the pin without me having to knock the pin through because there was much wear in the bottom bush. I put a sling around the cylinder and carefully took the weight with the Poclain while I slid the bottom cylinder shackle pin out.

After I had cleaned the bits and pieces up, the new cylinder was lifted into place using the Poclain and the cylinder bottom pin slid partially through the bottom eye of the cylinder. There is some wear around 0.030" on the actual frame where the cylinder pins slide through but this will have to pass at the moment.

Aligning the top piston pin up proved to be more trouble trying to use the Poclain added to which I did not want to accidentally clout the Hymac with the said machine, so it was easier for me to get another of the lads there to physically lift the reconditioned ram vertical and hold it there while I put a sling around the top of the ram and connected a pull lift to the sling. I then connected the hydraulic hoses and used the Hymac to push the piston out to near where it should fit then hoisted it using the pull lift, after some effort the cylinder was duly fitted and the other one I fitted faster as I then knew the best way to tackle the job. The only other issue was that I could not get the circlip back on the top of the second ram so I used a ratchet strap to pull the cylinders together and then the circlip fitted no problem.

I did have a quick play on the machine and it now works as it should; the right hand ram (nearest the cab) had the inner seals gone and the oil was bypassing them so she would not lift the boom under load, so another job bites the dust but lots left yet.

Jeremy

-

Jeremy Rowland

Topic author - Moderator

- Posts: 8677

- Joined: Sun Aug 05, 2007 8:36 pm

- Real name: Jeremy Rowland

- Has thanked: 1873 times

- Been thanked: 1692 times

Re: Hymac 580BT 1969

I had today up at Andrew's farm working on the Hymac; photos to come later when I have resized them, the plan was basically to strip off the dipper arm as I suspected that it may have cracked on the fork. In the event this turned out not to be the case although I suspect that the machine has a non-standard pin fitted through the fork.

Happy that she was not cracked I turned my attention to the removal of the dipper arm ram; I have a re-con ram that was ready to go straight on, the only issue encountered with the removal of the ram was that the pin securing the cylinder (a piece of bent wire) proved to be awkward to take out, my thanks to mechman Norman who helped out with this.

Once the wire was out the pins easily knocked out and Andrew lifted the ram off using his JCB Tele-handler; looking at the old ram the bushes were well worn due to too much grease (none, dry as a bone) to be expected for an old nail I suppose. Anyway we lifted the re-con ram on only to be faced with a new problem, the ram eye was too wide for the dipper arm!

The re-con ram was from a 580BT but at sometime in the past for whatever reason Hymac must have altered the width of the eye this only left two options; one to remove material from the wider eye, or two remove material from the dipper arm boss. After discussion with Andrew it was decided to remove material from the dipper using his 9" angle grinder and slitting discs, this was done with no real detrimental weakening of the boss, and the ram was duly fitted.

this only left two options; one to remove material from the wider eye, or two remove material from the dipper arm boss. After discussion with Andrew it was decided to remove material from the dipper using his 9" angle grinder and slitting discs, this was done with no real detrimental weakening of the boss, and the ram was duly fitted.

I did test the digger out although she leaks oil from one of the two flexi-hoses which are well knackered anyway; while I was there I checked the thread and length of these two hoses and will get some new ones made ready for fitting at some point in the future, it was 6:30 gone by the time I left there so a good days work done, I will post photos once they have been resized but a good wash and bed are calling.

Jeremy

Happy that she was not cracked I turned my attention to the removal of the dipper arm ram; I have a re-con ram that was ready to go straight on, the only issue encountered with the removal of the ram was that the pin securing the cylinder (a piece of bent wire) proved to be awkward to take out, my thanks to mechman Norman who helped out with this.

Once the wire was out the pins easily knocked out and Andrew lifted the ram off using his JCB Tele-handler; looking at the old ram the bushes were well worn due to too much grease (none, dry as a bone) to be expected for an old nail I suppose. Anyway we lifted the re-con ram on only to be faced with a new problem, the ram eye was too wide for the dipper arm!

The re-con ram was from a 580BT but at sometime in the past for whatever reason Hymac must have altered the width of the eye

I did test the digger out although she leaks oil from one of the two flexi-hoses which are well knackered anyway; while I was there I checked the thread and length of these two hoses and will get some new ones made ready for fitting at some point in the future, it was 6:30 gone by the time I left there so a good days work done, I will post photos once they have been resized but a good wash and bed are calling.

Jeremy

-

Jeremy Rowland

Topic author - Moderator

- Posts: 8677

- Joined: Sun Aug 05, 2007 8:36 pm

- Real name: Jeremy Rowland

- Has thanked: 1873 times

- Been thanked: 1692 times

Re: Hymac 580BT 1969

The first four photos show the dipper arm mounting pin; because this pin was turning it caused me to think that the boom fork boss had cracked, but when I took the end off and found the washer behind it I knew that was not the case.

The rest of the photos show the replacement of the dipper ram and one of Andrew trimming the dipper eye boss for me with his angle grinder

Back together now but not fully repaired I need to replace the two flexi-feed hoses which have perished; I did not over tighten them when I put them back on as I knew that they would have to come off again, I noticed after I had back filled the hole I dug to rest the dipper in that there was an oil leak so I assume that it was one of these two hoses? By that time it was time for me to depart for home and as I was knackered I just decided to leave it till next time.

Jeremy

The rest of the photos show the replacement of the dipper ram and one of Andrew trimming the dipper eye boss for me with his angle grinder

Back together now but not fully repaired I need to replace the two flexi-feed hoses which have perished; I did not over tighten them when I put them back on as I knew that they would have to come off again, I noticed after I had back filled the hole I dug to rest the dipper in that there was an oil leak so I assume that it was one of these two hoses? By that time it was time for me to depart for home and as I was knackered I just decided to leave it till next time.

Jeremy

-

Jeremy Rowland

Topic author - Moderator

- Posts: 8677

- Joined: Sun Aug 05, 2007 8:36 pm

- Real name: Jeremy Rowland

- Has thanked: 1873 times

- Been thanked: 1692 times

-

Jeremy Rowland

Topic author - Moderator

- Posts: 8677

- Joined: Sun Aug 05, 2007 8:36 pm

- Real name: Jeremy Rowland

- Has thanked: 1873 times

- Been thanked: 1692 times

Re: Hymac 580BT 1969

Andy80 wrote:Very interesting to read about your excellent boom and dipper ram work. Glad that you took a lot of pics

Thanks Andy

Jeremy

-

Jeremy Rowland

Topic author - Moderator

- Posts: 8677

- Joined: Sun Aug 05, 2007 8:36 pm

- Real name: Jeremy Rowland

- Has thanked: 1873 times

- Been thanked: 1692 times

Re: Hymac 580BT 1969

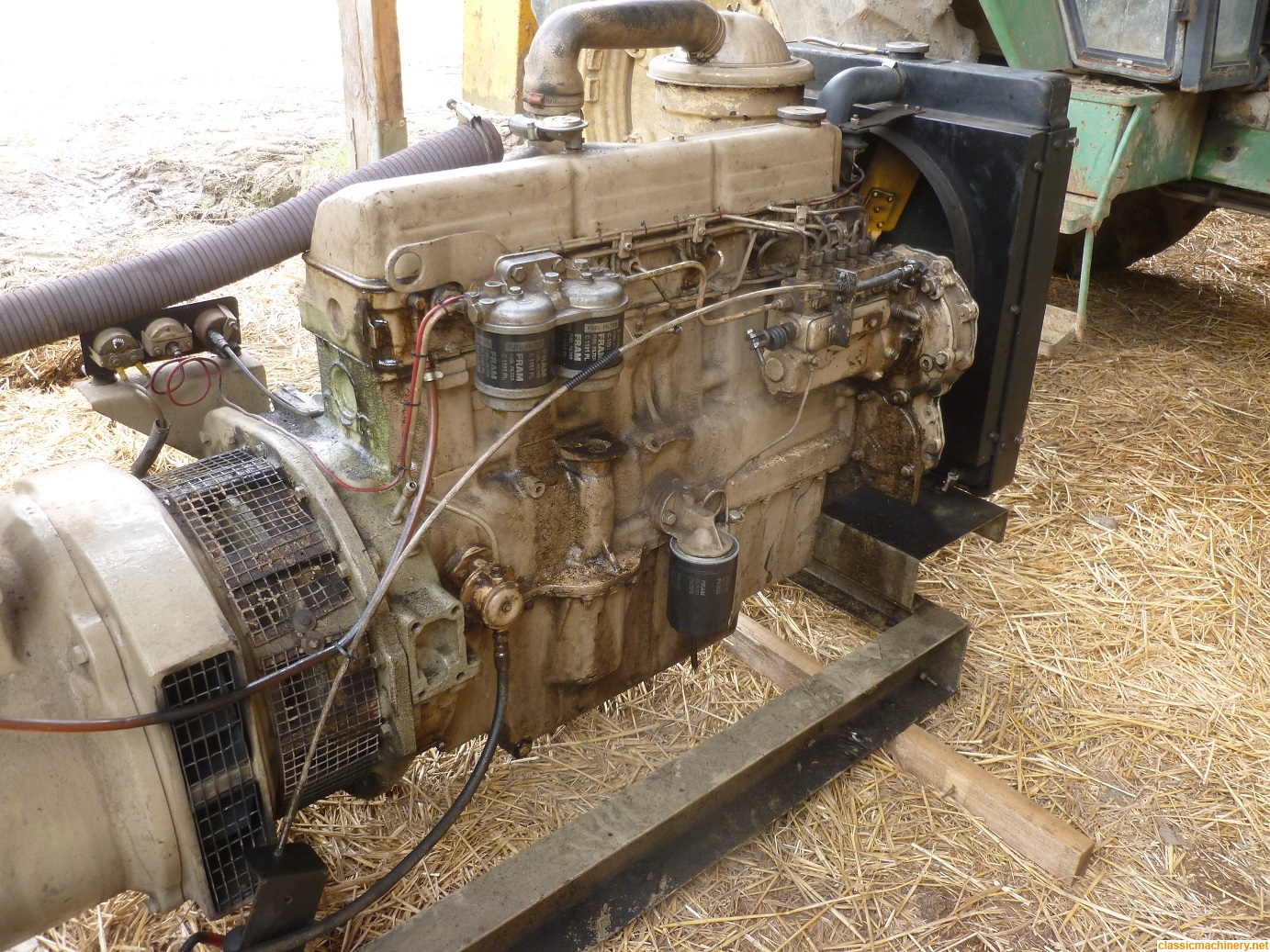

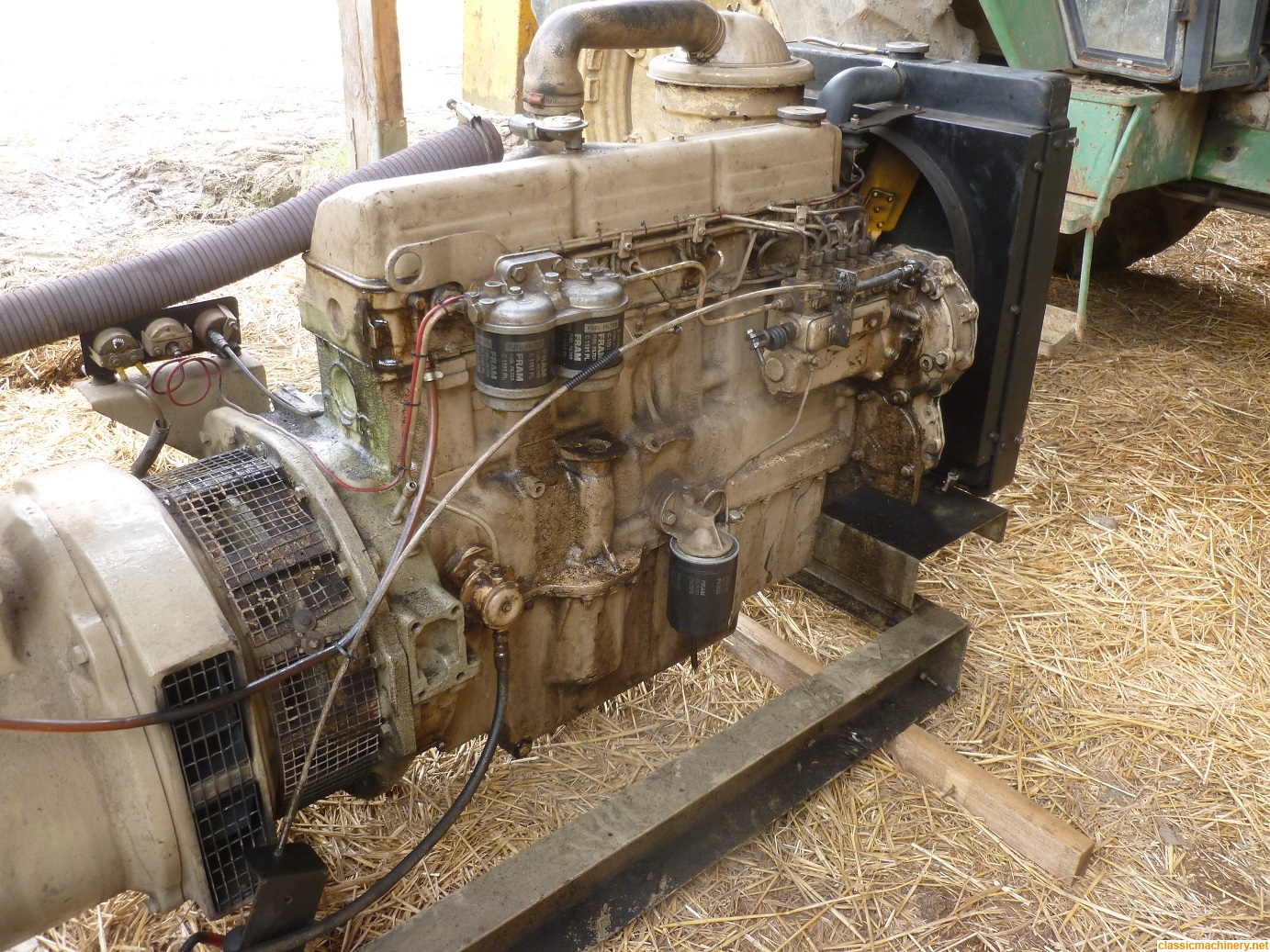

I had a flying visit up there today but did not stay too long; my main reason for being there was to unload an engine that I have purchased as a spare unit for the Hymac; although I like the Ford engines when they fail they usually 'stick a leg out of bed' (put a rod through the side) so on the vague off chance of this happening I did not want to find myself hunting for what is rapidly becoming a rare quantity.

At this point I must thank Norman Orrick who informed me that this engine which forms part of a redundant generator set had become available; the engine has not been worked hard so I purchased it from the LWR, and unloaded it using Andrew's JCB telehandler.

With the engine unloaded I headed off home but I had already spent the morning stripping the bucket ram which is the last ram that requires reconditioning; I have had a tool fabricated at work to release the cap; the said cap was tight and I found myself swinging off the extension bar in mid-air trying to undo the cap. After removing the tool and belting the cap with a hammer the tool then released it without excessive force; with the cap removed the only other difficult part was the main bush that is secured in the end of the cylinder and that took some getting out, once that was out the rod came out fairly easily. I have not bothered to strip the rod because the chrome is pitted and I either want it re-chromed or a new bar I don't want to mess about I just want the job done once correctly.

Jeremy

At this point I must thank Norman Orrick who informed me that this engine which forms part of a redundant generator set had become available; the engine has not been worked hard so I purchased it from the LWR, and unloaded it using Andrew's JCB telehandler.

With the engine unloaded I headed off home but I had already spent the morning stripping the bucket ram which is the last ram that requires reconditioning; I have had a tool fabricated at work to release the cap; the said cap was tight and I found myself swinging off the extension bar in mid-air trying to undo the cap. After removing the tool and belting the cap with a hammer the tool then released it without excessive force; with the cap removed the only other difficult part was the main bush that is secured in the end of the cylinder and that took some getting out, once that was out the rod came out fairly easily. I have not bothered to strip the rod because the chrome is pitted and I either want it re-chromed or a new bar I don't want to mess about I just want the job done once correctly.

Jeremy

-

Jeremy Rowland

Topic author - Moderator

- Posts: 8677

- Joined: Sun Aug 05, 2007 8:36 pm

- Real name: Jeremy Rowland

- Has thanked: 1873 times

- Been thanked: 1692 times

Re: Hymac 580BT 1969

While I have not been up to any of my machines to carry out any work on them I have been trying to source parts and get bits patched up for the 580BT; the bucket link is naturally badly worn and was also cracked. looking at it you can see where it has been welded up in the past so the digger has taken a good hammering in her past life.

I got the two 'new' cracks welded up as can be seen in the photo's, the next issue is the worn bush housing which is oval; I am getting one of the lads to do a minimum clean up skim on his boring machine and another lad to turn me an 'over-size' bush, I have no idea what clearance should be between the pin and bush? I would have guessed around 0.010" to 0.015" the current bus sizes measure 0.020" over their 2" inside diameter. the centers between the bushes is 18"

the centers between the bushes is 18"

Jeremy

I got the two 'new' cracks welded up as can be seen in the photo's, the next issue is the worn bush housing which is oval; I am getting one of the lads to do a minimum clean up skim on his boring machine and another lad to turn me an 'over-size' bush, I have no idea what clearance should be between the pin and bush? I would have guessed around 0.010" to 0.015" the current bus sizes measure 0.020" over their 2" inside diameter.

Jeremy

Who is online

Users browsing this forum: No registered users and 30 guests