Well I left the turbo soaking in some old derv last week; a good friend of mine suggested leaving it for longer, anyway I had an idea of my own so using some bolts and nuts I devised a simple method of using these to exert pressure on the casing, a bit like a jack. Now although I did protect the weaker part of the casing, I did not want to put too much pressure on, so after using three bolts at different angles it appears that the turbo has started to come apart albeit by a few thou. The result is that I can now get some freeing oil in and be sure that it is reaching the part that is still stuck, I opted to let it soak again now with a gap that will permit the fluid to enter and hopefully free it off.

While the turbo was soaking my next task turned into another real saga; one of the engine jobs that is a 'must do' for me is to change the engine oil and filter, the old filter which is the screw on canister type is so old that it has the Hy-mac name and part number on it. After using a filter wrench the old filter eventually gave up and I broke the seal on it, however I had a real bad feeling about this filter.

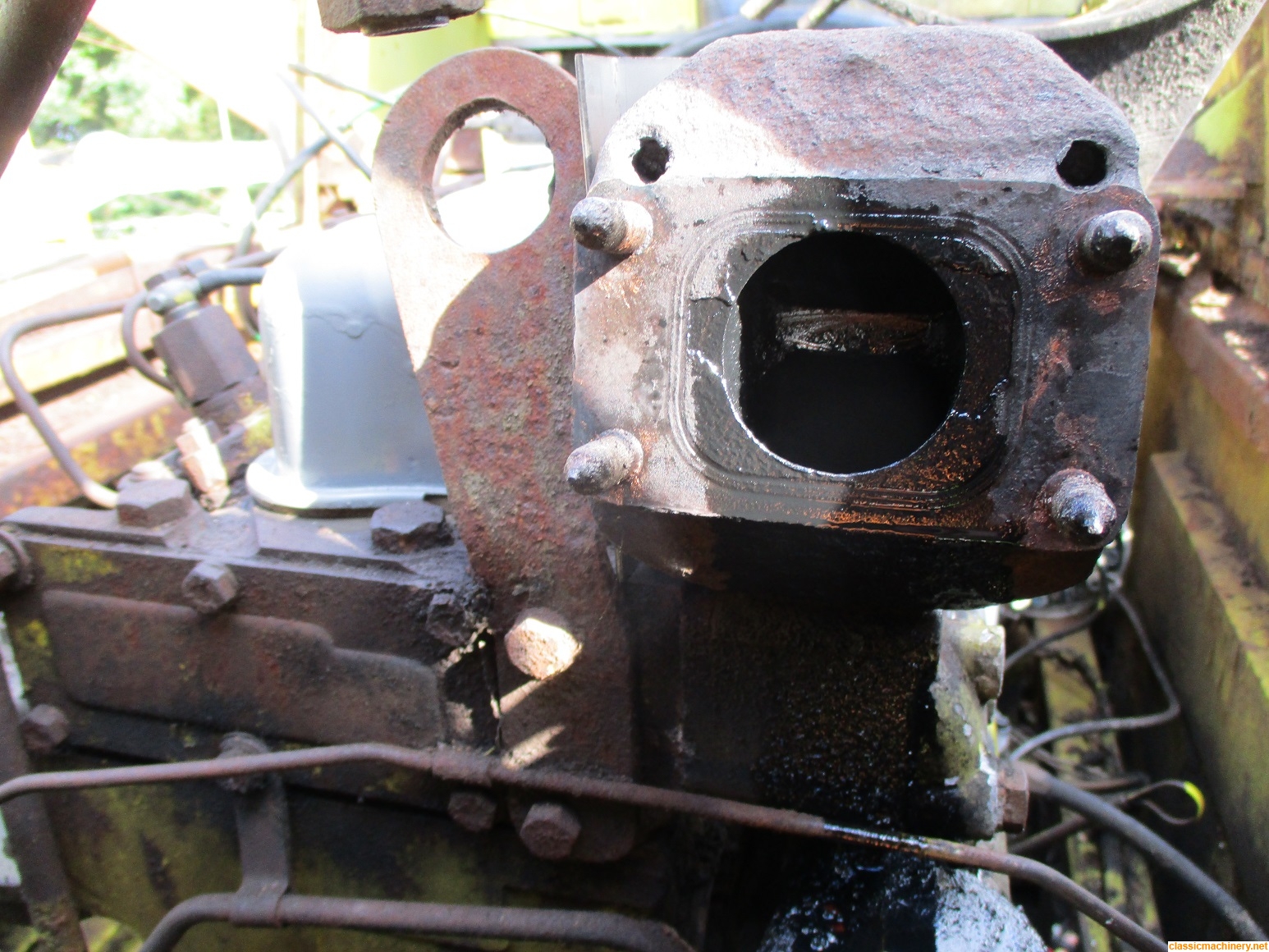

The filter is an upside down canister type

daft idea to start with

now my hand would just fit between the bottom of this filter and the inlet manifold, it crossed my mind that there may not be enough room to get the filter out, after unscrewing the filter this worst case scenario was then realized

Quickly I could see there was only one way to get the filter off which was to unscrew the two bolts that hold the filter housing to the side of the engine block which would allow that to drop out of the way enough for me to remove the filter. Grr what a malarkey that was, but got the job done in the end, only the British could design such a daft idea as that! Just to add to any saga the weather was crap too, but not a bad day overall plus two other smaller tasks completed.

Jeremy