As elsewhere on the board I extracted #3 after a really low compression reading, but reposting here to just keep it in one place now.

Original URL: http://gallery.pipandphil.com/Vehicles/workshop/jcbpiston1.jpg

Liner to match

Original URL: http://gallery.pipandphil.com/Vehicles/workshop/jcbliner.jpg

New liner in, after some shennanigans with cap marking being altered

Original URL: http://gallery.pipandphil.com/Vehicles/workshop/jcb_newpot.jpg

Head back on, painted the rocker cover and I've bought a replacement rocker cover cap because one of the legs has fell off the old one. I know its the wrong shade of yellow for the machine, bu its better than rust.

Original URL: http://gallery.pipandphil.com/Vehicles/workshop/jcb_headon.jpg

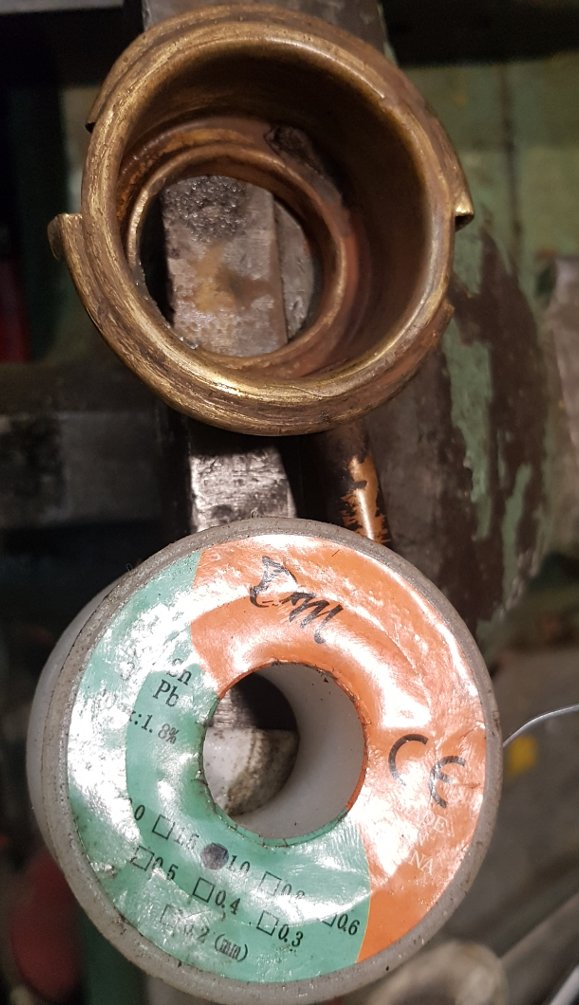

I took off the rad at the suggestion of someone here and backflushed it, and got all the grunge off the bottom with the steamer, then pressure tested it as I have always been suspicious of the top tank as its damaged by some idiot in the past standing on it. And it was leaking between the filler neck and radiator top tank, and the filler neck itself was twisted. So I bought a replacement neck off ebay and sweated the old neck off.

Original URL: http://gallery.pipandphil.com/Vehicles/workshop/jcb_rad_oldneck.jpg

Its oval too, you can just make this out.

Original URL: http://gallery.pipandphil.com/Vehicles/workshop/jcb_rad_oldneck2.jpg

Soldered new neck in, and holding at 5psi. Yes my "testing" rig is bits of old inner tube wrapped round the spigots and hose clipped to stop leakage, but it works and it was free. I painted it matt black after this to keep corrosion at bay and its back in the machine now.

Original URL: http://gallery.pipandphil.com/Vehicles/workshop/jcb_rad_testing.jpg

I picked up the correct 3c canister air filter off ebay to replace the transit pancake housing it had on it, and bead blasted it and painted it and put new filters in it, but no photo of that. I can't find anyone selling a intake hose to connect it the manifold so I'll have to make something to suit.

Besides that, I replaced the tacho drive box, and ordered a new tacho cable, vicary have them in stock for the 3c iii if anyone is searching still, and some other seller on ebay who wanted double the price for postage etc. Now waiting for more stuff to arrive & I have next week off to get some more stuff done if it turns up.